Metallographic Cast Iron Etchants

The most common etchants for cast irons is 2% Nital, however, a good resouce for additional etchants can be found with the etchant database provided by PACE Technologies

CAUTION: Safety is very important when etching. Be sure to wear the appropriate protective clothing and observe all WARNINGS on chemical manufacuters SDS (Safety Data Sheets). Also review the COMMENTS and CONDITIONS Section for each etchant.

Sample Preparation:

Cast Irons are difficult materials to prepare properly because the graphite nodules or the graphite flakes are easily fractured and pulled out during preparation. By minimizing the sectioning damage and starting with a modest grit size SiC paper, retaining these difficult particles can be accomplished.

Recommended Etchants

| Etchant | Conc. | Conditions | Comments |

|---|---|---|---|

|

Nital:

Ethanol Nitric acid |

100 ml 1-10 ml |

Seconds to minutes | Do not exceed 10% nitric acid -explosive |

|

KLEMMS 2:

Saturated sodium thiosulfate Potassium metabisulfite |

250 ml 25 grams |

Seconds to minutes | Dual phase tint etchant. Ferrite is light or dark blue, martensite brown and black, retained austenite white. Heating to 40°C will enhance the staining |

|

| Nodular Cast Iron, 2% Nital,, 100X (DIC) |

|

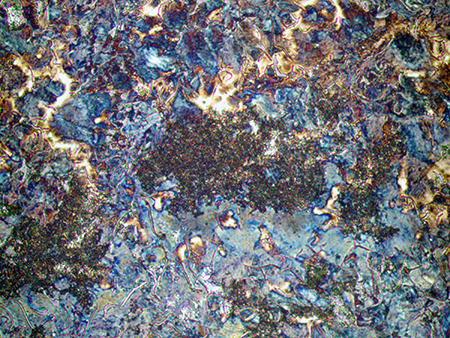

| Gray Cast Iron, Klemms 2 tint etch, 40°C, 1000X (BF). Blue is ferrite, brown is martensite, austenite is white |