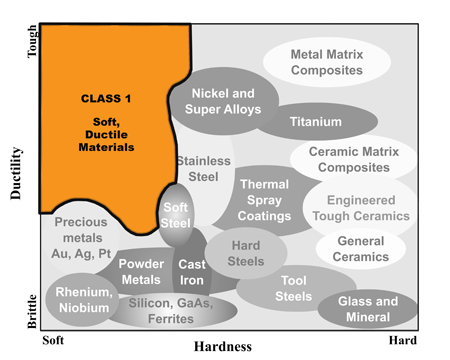

Boron Graphite Composite

Specimen Preparation (Class 1 Procedures)

|

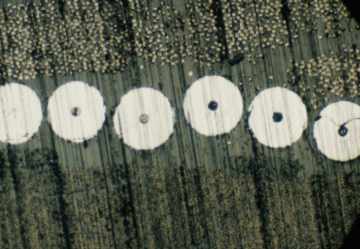

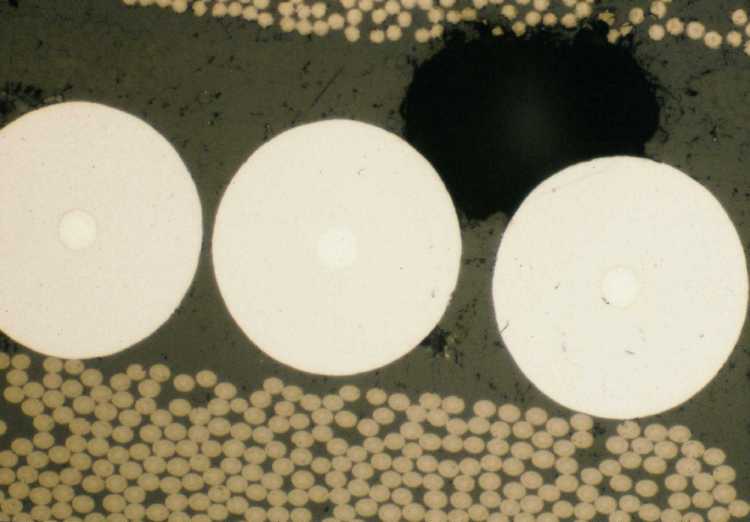

Boron-graphite composites are very difficult to prepare. Although the boron fibers provide additional flexture strength to the carbon fibers, the boron provides a real microstructural preparation challenge. The most important step in the preparation of boron/ graphite composites is in sectioning. If the boron fibers are chipped and excessively cracked during sectioning it is impossible to remove the damage and maintain the planar surface required for metallographic analysis. Cutting with a fine grit diamond blade is essential. Figure 1 shows a properly cut specimen with a fine grit blade, where all of the fibers are intact. In comparison, Figure 2 shows the severe damage that occurs even with a medium grit blade. Planar grinding, rough polishing and final polishing require the use of diamond lapping films to eliminate edge rounding of the polymer/boron fiber interface. Figure 3 shows the final surface finish on a properly prepared boron/ graphite composite. Note that there is no relief at the boron/polymer interface and thus an accurate characterization of this interface can be made.

SECTIONING

Diamond Wafering blade - fine grit / low concentration

MOUNTING

Castable Mounting with Epoxy or Acrylic resins

POLISHING

**Individual force is recommended as planar grinding with larger abrasives produces irreversible damage. Click here for more information on central vs. individual polishing force polishing.

|

|

| Fine grit diamond wafering blade | Medium grit diamond wafering blade |

|

| Figure 3. Boron graphite composite, Mag. 400X (B.F.) |

ETCHING

Common Etchants

CAUTION:Safety is very important when etching. Be sure to wear the appropriate protective clothing and observe all WARNINGS on chemical manufacuters SDS (Safety Data Sheets). Also review the COMMENTS and CONDITIONS Section for each etchant.