Copper Specimen Metallographic Preparation

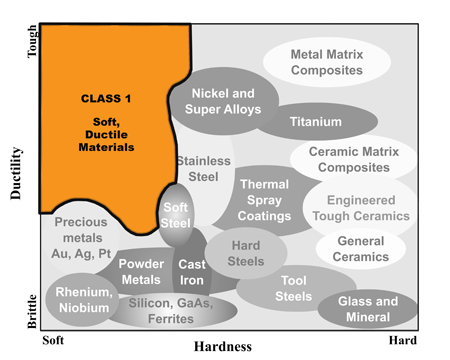

Specimen Preparation (Class 1 Procedures)

|

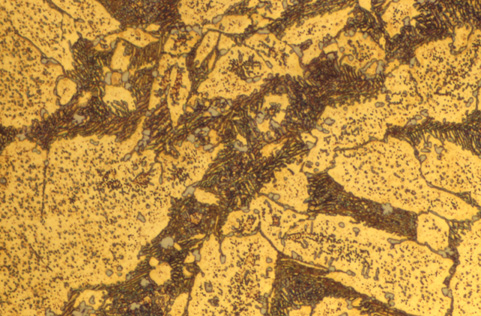

Copper and Copper Alloys Description:

Copper and its alloys are relatively soft materials which have a wide range of alloy applications.

Preparation Challenge:Copper and copper alloys are difficult to prepare because they have a tendency to work harden and have oxide inclusions. The result is that the oxide inclusions can become dislodged and scratch the surface. This scratching is more apparent following etching.

To minimize oxide pull-out, preparation damage can be minimized by using fine grit alumina grinding papers and polishing with polycrystalline diamond for the intermediate polishing step, followed by polishing with polycrystalline alumina.

Examples:| COPPER ALLOY PROCEDURES | |

|---|---|

Tough Pitch Copper |

Manganese-Aluminum Bronze |

Copper / Stainless Steel Weld |

Copper - Zinc alloys |

Nickel-Iron Bronze |

Brass  |