Graphite Composite

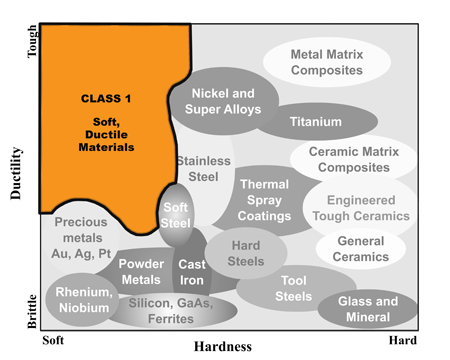

Specimen Preparation (Class 1 Procedures)

|

Glass reinforced composites are very useful materials, however microstructural preparation can be tricky. The best approach is to minimize the amount of cracking and chipping in the fibers as early in the preparation stage as is practical. This is accomplished by starting with 320 grit SiC or finer. For rough and final polishing, the use of a resilient polishing pad such as Black Chem, in combination with polycrystalline diamond and SIMAT colloidal silica produce a damage free surface ready for examination.

SECTIONING

Diamond Wafering blade - medium grit / low concentration

MOUNTING

Castable Mounting with Epoxy or Acrylic resins

POLISHING

*Required for central polishing force. Click here for more information on central vs. individual polishing force polishing.

|

| Longitudinal glass fiber orientation, 100X |

|

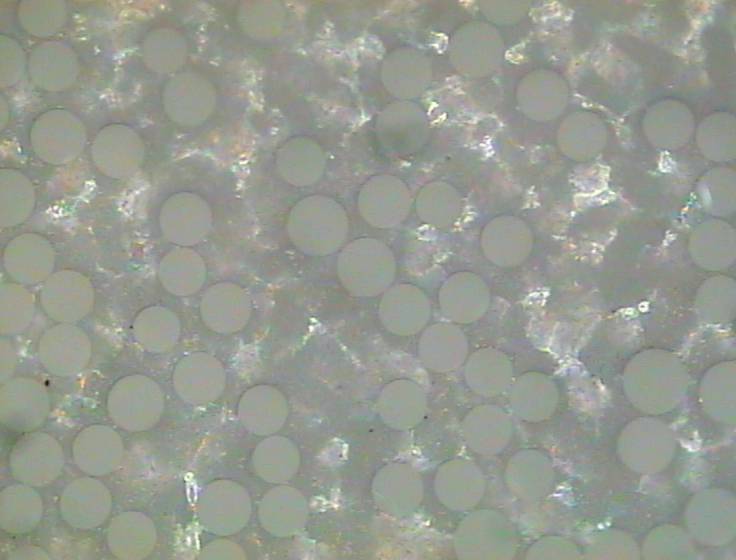

| Transverse glass fiber orientation, 500X |

ETCHING

Common Etchants

CAUTION:Safety is very important when etching. Be sure to wear the appropriate protective clothing and observe all WARNINGS on chemical manufacuters SDS (Safety Data Sheets). Also review the COMMENTS and CONDITIONS Section for each etchant.