Piezoelectric (PZT) Device

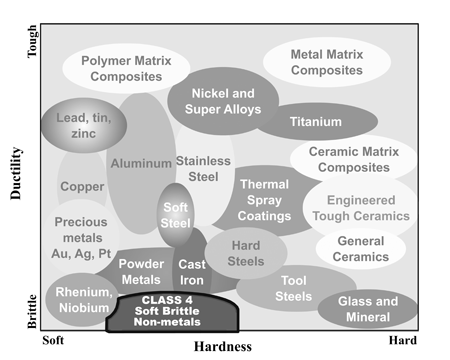

Specimen Preparation (Class 4 Procedures)

|

PZT, or piezoelectric, devices are very useful because they generate a voltage when mechanically deformed or vice versa.

PZT's are typically composed of lead, zirconium and titanate, which are processed at extremely high temperatures. PZT devices present the same challenges as polishing other brittle materials; however, they present the additional challenge of preparing other materials with significantly different properties (packaging materials, solders, coating, etc.). Specimen preparation must eliminate the preparation induced artifacts, as well as maintain the planarity of the specimen.

SECTIONING

Diamond wafering blade - medium grit/low concentration (if required)

MOUNTING

Castable epoxy or acrylic resins

POLISHING

*Required for central polishing force. Click here for more information on central vs. individual polishing force polishing.

|

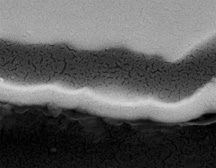

| PZT cross section with sputter coating, 200,000X, as polished |

|

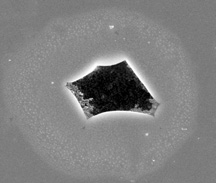

| Undesirable void in PZT, 31,000X, as polished |

ETCHING

Common Etchants

CAUTION:Safety is very important when etching. Be sure to wear the appropriate protective clothing and observe all WARNINGS on chemical manufacuters SDS (Safety Data Sheets). Also review the COMMENTS and CONDITIONS Section for each etchant.