Refractory Materials Metallographic Preparation

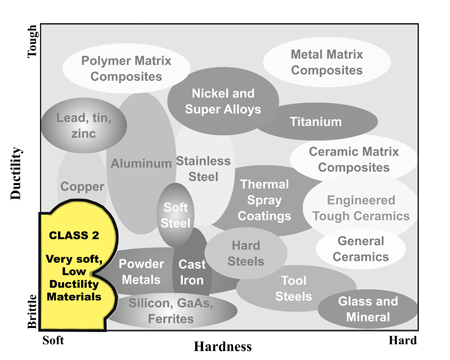

Specimen Preparation (Class 2 Procedures)

|

Description:

Refractory metals such as rhenium, niobium and tungsten have very high melting temperatures; however, they are typically very soft.

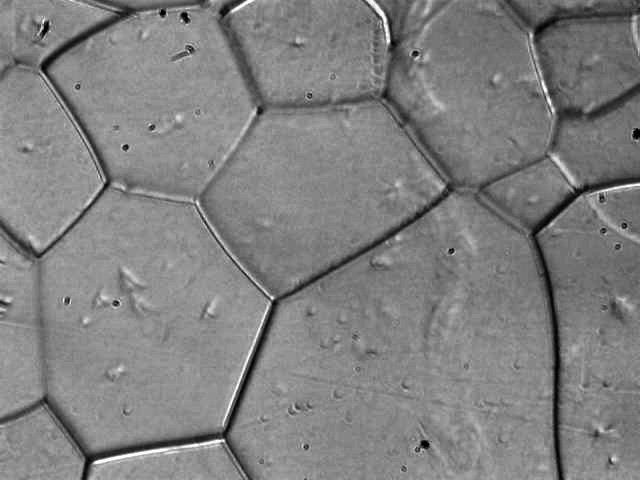

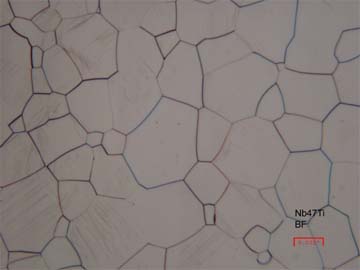

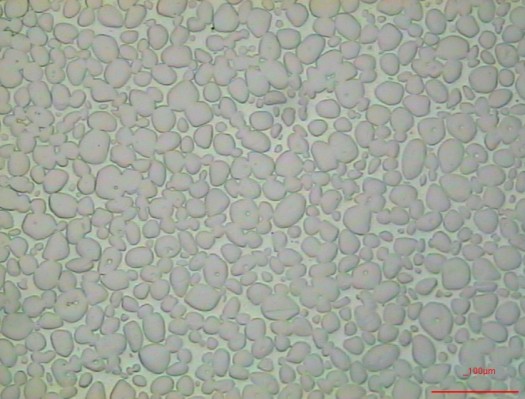

Preparation Challenge:Since refractory metals are very soft, any loose or fractured abrasive particles can easily embed. This makes specimen preparation very difficult because it gums up diamond grinding disks or specimen can become embedded with fractured SiC particles when ground with SiC papers. The key to preparation of these materials is to use tougher alumina abrasives and to chemically etch the specimen in between each grinding step. The purpose of etching is to remove the embedded particles so as not to carry them over to the next grinding step as contamination.

Examples:| REFRACTORY METAL PROCEDURES | |

|---|---|

Rhenium  |

Niobium  |

Tungsten

|

|