Stainless Steel / Copper Weld

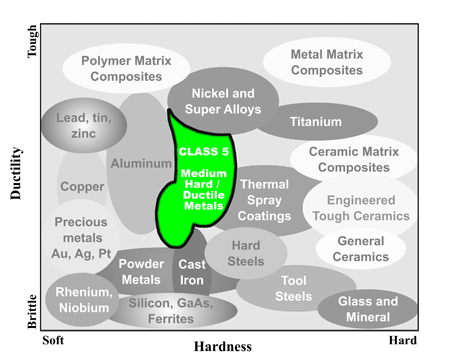

Specimen Preparation (Class 5 Procedures)

|

Stainless steel / copper welds are examined to determine the extent of diffusion of the stainless steel into the copper. This is undesirable because it significantly reduces the electrical conductivity of the copper. The key to polishing copper / stainless weld is to minimize smearing during cutting and initial grinding and to maintain the integrity of the inclusions in both the copper and stainless steel.

SECTIONING

MAXCUT Abrasive blade (Cat. No. MAX-C or MAX-I series)

MOUNTING

Compression Mounting with Phenolic, Epoxy or Diallyl Phthalate compression mounting resins

POLISHING

*Required for central polishing force. Click here for more information on central vs. individual polishing force polishing.

|

| Diffusion of Stainless Steel (gray) into copper, 200X B.F., (as polished) |

|

| Crack formed in Stainless Steel by welding operation, 200X B.F. (as polished) |

ETCHING

Common Etchants

CAUTION:Safety is very important when etching. Be sure to wear the appropriate protective clothing and observe all WARNINGS on chemical manufacuters SDS (Safety Data Sheets). Also review the COMMENTS and CONDITIONS Section for each etchant.