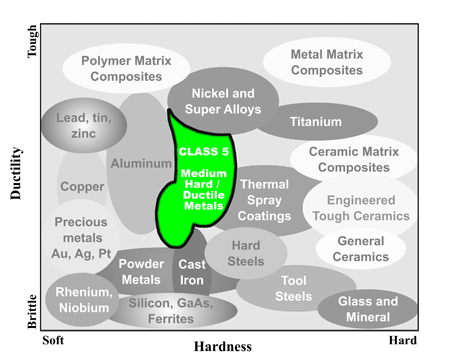

Steel-Fillet Welding

Specimen Preparation (Class 5 Procedures)

|

Welding is the process of joining two or more pieces of metal together. The process can use filler materials to aid in the welding process. Since the welding process involves metaling and fusing the metals, the microsctructure and orientation and positioning of the weld are important metallurgical features that often require sampling to control the quality of the production process. Microstructural preparation and analysis of welded parts is relatively simple and use basic metallographic procedures.

SECTIONING

MAXCUT Abrasive blade (Cat. No. MAX-A or MAX-D series)

MOUNTING

Compression Mounting with Phenolic, Epoxy or Diallyl Phthalate compression mounting resins (if required)

POLISHING

*Required for central polishing force. Click here for more information on central vs. individual polishing force polishing.

|

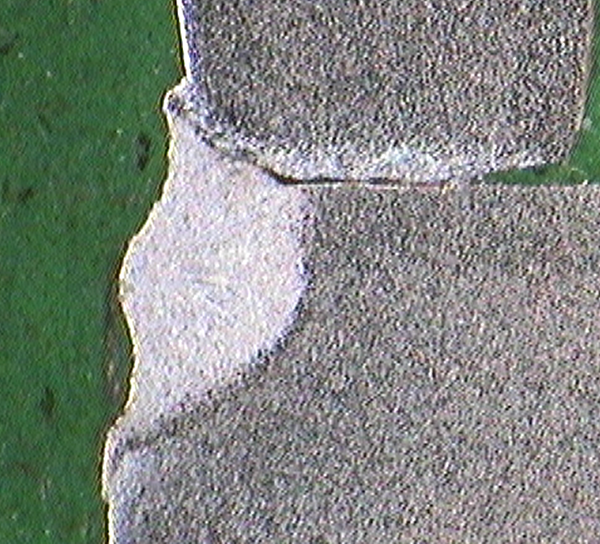

| Carbon Steel Weld, mag. 50X, Etched 2% Nital |

|

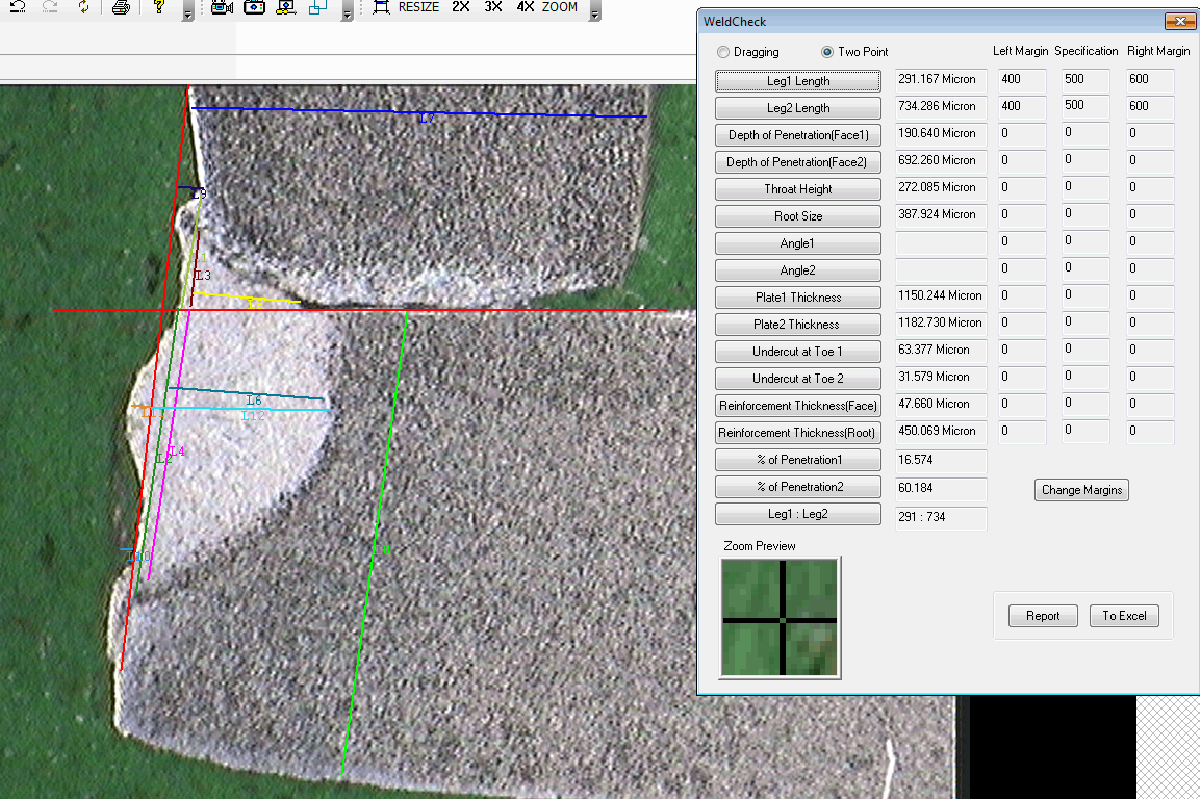

| Weld Check Dimensional Analysis Software |

ETCHING

Common Etchants

CAUTION:Safety is very important when etching. Be sure to wear the appropriate protective clothing and observe all WARNINGS on chemical manufacuters SDS (Safety Data Sheets). Also review the COMMENTS and CONDITIONS Section for each etchant.