Metallographic Hardness Testing Information

Metallographic Hardness Testing InformationIntroduction

Hardness Testing provides useful information, which can be correlated to tensile strength, wear resistance, ductility, and other physical characteristics of the material. Hardness testing is therefore useful for monitoring quality control and for aiding in the materials selection process.

The following table provides a relative scaling between the various hardness testing values, however these comparisons are not exact since the values will vary for different materials.

| Brinell (10 mm ball, 3000 kg load) |

Vickers (120 kg) |

Rockwell C (150 kg load) |

Rockwell B (1/16-inch ball, 100 kg) |

|---|---|---|---|

| 800 | - | 72 | - |

| 780 | 1220 | 71 | - |

| 725 | 1060 | 67 | - |

| 652 | 867 | 63 | - |

| 601 | 476 | 60 | - |

| 514 | 587 | 53 | 120 |

| 451 | 489 | 47 | 117 |

| 401 | 423 | 43 | 114 |

| 351 | 361 | 38 | 111 |

| 301 | 305 | 33 | 107 |

| 249 | 250 | 25 | 101 |

| 200 | 199 | 16 | 93 |

| 152 | 150 | - | 82 |

| 105 | 110 | - | 62 |

| 76 | 80 | - | 37 |

Rockwell Hardness

Rockwell hardness (HR) is an indentation hardness test that is determined with a spheroconical penetrator, or hard steel ball, that is forced into the specimen surface. The test is accomplished by bringing the specimen into contact with the penetrator and allowing the penetrator to be slowly forced into the specimen surface by a series of weights acting through a system of levers. After the load is released, a dial pointer or LED screen indicates the hardness number.

Typical Applications:

- Quality control for metal heat treatment

- Materials receiving inspection

- Evaluation of welds in steels and other metal alloys

- Failure analysis

Brinell Hardness

To determine a Brinell hardness number (BHN), a 10 mm diameter steel ball is typically used as an indenter with a 3,000 kgf (29 kN) force. For softer materials, a smaller force is used; for harder materials, a tungsten carbide ball is used. The BHN can also be converted into the ultimate tensile strength (UTS), although the relationship is dependent on the material, and therefore is only an empirically based value.

Vickers Hardness

The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter can be used for all materials irrespective of hardness. The Vickers test can be used for all metals and has one of the widest scales among hardness tests. The unit of hardness given by the test is known as the Vickers Pyramid Number (HV) or Diamond Pyramid Hardness (DPH).

Microhardness

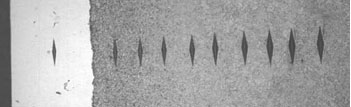

Microhardness testers are both mechanical and optical measuring tools. The indent is produced by applying a known load to the specimen and then measuring the size of the appropriate diagonals either optically or with image analysis software. Microhardness is primarily determined with either a Knoop or Vickers indenter under test loads in the range of 1 to 2000 gram-force. Microhardness is used to measure the hardness of specific phases, small particles, and for brittle materials. Figure 10-2 shows the Knoop microhardness indents for a heat treated steel specimen.

Knoop hardness (HK) number is based on the size of the indent that a rhombic-based, pyramidal diamond indenter produces under a known applied load. The HK number is calculated by dividing the applied load (kilogram-force) by the projected area of the indentation (square millimeters).

Knoop hardness indents in a hardened steel.

The Vickers hardness (HV) number is obtained by dividing the applied load in kilogram-force by the surface area of the indentation. The area of the indentation produced from the Vickers square-based pyramidal diamond is determined by the mean distance between the two diagonals of the indentation.

Vickers hardness indent.

Rockwell Regular Test Blocks

| Hardness Scale | Part No. | Penetrator | Load | Ranges | Material |

|---|---|---|---|---|---|

| A Scale | RA10 | C Diamond | 60 Kg | A60-A84 | Steel |

| A Scale | RA20 | C Diamond | 60 Kg | A20-A59 | Brass |

| A Scale | RA30 | A Diamond (Carbide) | 60 Kg | A88 & up | Carbide |

| B Scale | RB10 | 1/16" Ball | 100 Kg | B10-B92 | Steel |

| B Scale | RB20 | 1/16" Ball | 100 Kg | B90-B130 | Steel |

| C Scale | RC10 | C Diamond | 150 Kg | All | Steel |

| D Scale | RD10 | C Diamond | 100 Kg | All | Steel |

| E Scale | RE10 | 1/8" Ball | 100 Kg | All | Brass |

| F Scale | RF10 | 1/16" Ball | 60 Kg | All | Brass |

| G Scale | RG10 | 1/16" Ball | 150 Kg | G2.5-G64 | Brass |

| G Scale | RG20 | 1/16" Ball | 150 Kg | G66 & up | Steel |

| H Scale | RH10 | 1/8" Ball | 60 Kg | All | Brass |

| K Scale | RK10 | 1/8" Ball | 150 Kg | All | Brass |

| L Scale | RL10 | 1/4" Ball | 60 Kg | All | Brass |

| M Scale | RM10 | 1/4" Ball | 100 Kg | All | Brass |

| P Scale | RP10 | 1/4" Ball | 150 Kg | All | Brass |

| R Scale | RR10 | 1/2" Ball | 60 Kg | All | Brass |

| S Scale | RS10 | 1/2" Ball | 100 Kg | All | Brass |

| V Scale | RV10 | 1/2" Ball | 150 Kg | All | Brass |

NOTE: Aluminum Test Blocks are available in "B", "E", "F", "G", "H",, "K" Scales, however the range is more limited

Rockwell Superficial Test Blocks

| Hardness Scale | Part No. | Penetrator | Load | Ranges | Material |

|---|---|---|---|---|---|

| 15N Scale | S15N10 | N Diamond | 15 Kg | All | Steel |

| 30N Scale | S30N10 | N Diamond | 30 Kg | All | Steel |

| 45N Scale | S45N10 | N Diamond | 45 Kg | All | Steel |

| 15T Scale | S15T10 | 1/16-inch Ball | 15 Kg | All | Brass |

| 30T Scale | S30T10 | 1/16-inch Ball | 30 Kg | All | Brass |

| 45T Scale | S45T10 | 1/16-inch Ball | 45 Kg | All | Brass |

| 15W Scale | S15W10 | 1/8-inch Ball | 15 Kg | All | Brass |

| 30W Scale | S30W10 | 1/8-inch Ball | 30 Kg | All | Brass |

| 45W Scale | S45W10 | 1/8-inch Ball | 45 Kg | All | Brass |

| 15X Scale | S15X10 | 1/4-inch Ball | 15 Kg | All | Brass |

| 30X Scale | S30X10 | 1/4-inch Ball | 30 Kg | All | Brass |

| 45X Scale | S45X10 | 1/4-inch Ball | 45 Kg | All | Brass |

| 15Y Scale | S15Y10 | 1/2-inch Ball | 15 Kg | All | Brass |

| 30Y Scale | S30Y10 | 1/2-inch Ball | 30 Kg | All | Brass |

| 45Y Scale | S45Y10 | 1/2-inch Ball | 45 Kg | All | Brass |

NOTE: Aluminum test blocks are also available upon request.

Rockwell Testing Accessories

Diamond Penetrators

Each diamond penetrator is mounted in conformity with its grain structure to assure balanced pressure and prevent early wear or breakage. They are precision ground lapped and polished. We also subject each diamond penetrator to a strict performance test before is approved for sale.

| Part No. | Description |

|---|---|

| P1010 | Standard "C" Diamond Penetrator |

| P1020 | Standard "N" Diamond Penetrator |

| P1030 | Carbide "A" Diamond Penetrator |

| P1040 | 'Versitron'® - type "C" Diamond |

| P1045 | 'Versitron'® - type "N" Diamond |

| P1050 | 'Indentron'® - type "C" Diamond |

| P1060 | 'Indentron'® - type "N" Diamond |

| P1070 | "C" & "N" Combo Slip-in Diamond Penetrator |

| P1080 | "C" Portable Diamond Penetrator |

| P1090 | 'Veritron' - type Tapered Diamond |

Versitron® and Indentron® are Registered trademarks for Newage Testing Instruments, Inc.

Ball Penetrators| Part No. | Description |

|---|---|

| P2010 | 1/16-inch Ball Penetrator Unit |

| P2015 | 1/16-inch Balls (50 each) |

| P2020 | 1/8-inch Ball Penetrator Unit |

| P2025 | 1/8-inch Balls (25 each) |

| P2030 | 1/4-inch Ball Penetrator Unit |

| P2035 | 1/4-inch Balls |

| P2040 | 1/2-inch Ball Penetrator Unit |

| P2045 | 1/2-inch Balls |

| P2055 | 1/16-inch Carbide Balls |

Anvils

| Part No. | Description |

|---|---|

| A1010 | Pedestal Spot (1/4-inch) Anvil |

| A1020 | 1-1/2-inch Flat Anvil |

| A1030 | 2-1/2-inch Flat Anvil |

| A1040 | Shallow "V" Anvil |

| A1050 | Standard "V" Anvil |

| A1060 | 4-inch "V" Anvil |

| A1070 | Gooseneck Anvil |

| A1080 | Diamond Spot Anvil |

Other Rockwell Accessories

| Part No. | Description |

|---|---|

| A2010 | Index Adjusting Unit |

| A2020 | Cross Pin Unit (For Dials) |

| A2030 | Elevating Unit Oil (1/2 pint) |

| A2040 | Dash Pot Oil (1/2 pint) |

| A3010 | Gosseneck Adapter 2-1/2-inch |

| A3020 | 8-inch Testing Table |

| A3030 | Jack Rest (8-inch or 12-inch) |

| A3040 | Extension Support |

| A3050 | Bulbs |

Brinell Test Blocks and Accessories

All Brinell Test Blocks come certified to applicable standards. We adhere to a strict procedure for our calibration process and the accuracy of our tester is maintained using a proving ring and load cell both traceable to N.I.S.T. The readings are done using a stage micrometer, which is also calibrated and traceable to N.I.S.T.

| Part No. | Description | Range |

|---|---|---|

| B3000 | 3000 Kg Load 10mm Ball | All Hardness Ranges |

| B2000 | 2000 Kg Load 10mm Ball | All Hardness Ranges |

| B1500 | 1500 Kg Load 10mm Ball | All Hardness Ranges |

| B1000 | 1000 Kg Load 10mm Ball | All Hardness Ranges |

| B0500 | 500 Kg Load 10mm Ball | All Hardness Ranges |

| B0250 | 250 Kg Load 10mm Ball | All Hardness Ranges |

| B0187 | 187.5 Kg Load 10mm Ball | All Hardness Ranges |

| BT010 | Telebrinell Test Blocks | All Hardness Ranges |

| Part No. | Description |

|---|---|

| P3010 | 10mm Steel Balls |

| P3020 | 10mm Carbide Balls |

Microhardness Test Blocks and Accessories

We manufacture our micro hardness test blocks to exceed industry standards. All of our micro test blocks are mirror polishes and mounted to provide the best possible test surface. Each mirror polished Heavy Load Vickers test block has the same surface area provided by our Rockwell test blocks, so that you get the most test opportunities for your money.

| Part No. | Description | Range |

|---|---|---|

| MV010 | Vickers (1 gram to 1000 grams) | All Ranges |

| MV020 | Heavy Load Vickers (1 Kg to 50 Kg) | All Ranges |

| MK010 | Knoop (1 gram to 1000 grams) | All Ranges |

NOTE: When ordering please specify Knoop or Vickers, Load and the Hardness Range you require.

| Part No. | Description |

|---|---|

| P1110 | Vickers Diamond Penetrator |

| P1120 | Knoop Diamond Penetrator |