Metallographic Polishing Pads with Adhesive Information

Polishing Cloths

Polishing is the most important step in preparing a specimen for microstructural analysis. It is the step which is required to completely eliminate previous damage. Ideally the amount of damage produced during cutting and grinding was minimized through proper blade and abrasive grinding so that polishing can be minimized.

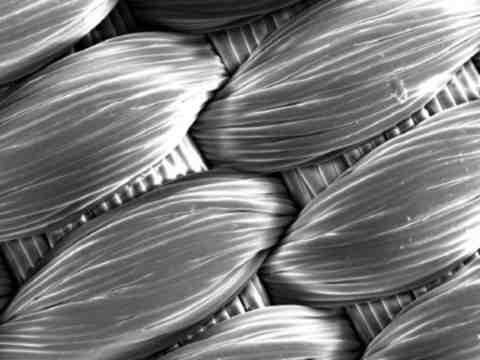

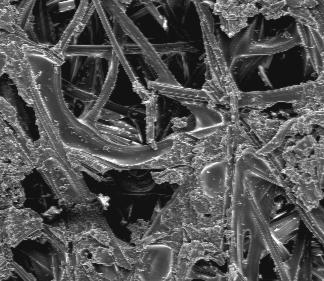

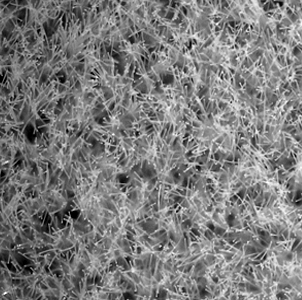

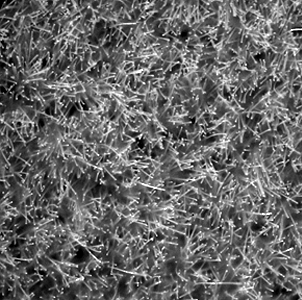

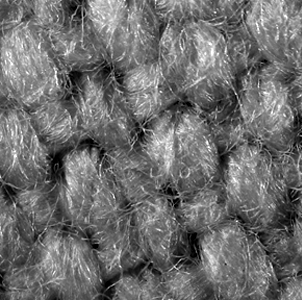

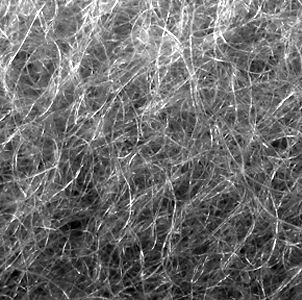

Cloths for polishing vary by the height of their fiber, known as the nap and by the stiffness or resiliency of the fiber. In general, the lower nap (also non-woven) and stiffer fiber cloths are used for the rough polishing steps. These types of polishing cloths or pads are very effective in removing sectioning damage done by cutting and coarse grinding. Conversely, higher napped polishing cloths provide a more gentle abrasive interaction for the final polish. The Polishing Pads are available with either a pressure sensitive adhesive (PSA) or on a magnetic backing. The following is a list of most common polishing cloths:

Polishing Pad Selection Guidelines

Recommended Procedures (Polishing Pads)

- Place pad on a flat lap plate

- Pre-charge pad with abrasive suspension, paste or powder

- Apply necessary lubricant

- Begin polishing with lower force to avoid tearing pad

- Clean specimen and pad for final 10-15 seconds of polishing cycle

- Clean and dry specimens

Polishing Process Description

Polishing can be broken into two stages: rough and final polishing. Proper rough polishing removes all subsurface damage produced during cutting and grinding. In most cases this is accomplished with polycrystalline diamond abrasives and low napped polishing cloths. The final polishing step should be kept to a minimum and used only to clean up surface blemishes. Note that excessive final polishing times can result in phase relief, edge rounding, smeared material and inclusion pull-out. Final polishing is accomplished with high napped cloths and fine graded alumina or colloidal silica abrasives.

Minimizing Polishing ArtifactsTo minimize polishing artifacts such as edge rounding, phase relief, smeared metal, grain pull-out and inclusion pull-out, the polishing time needs to be kept to a minimum. This can be accomplished by:

- minimizing sectioning damage

- grinding with the finest feasible abrasives

- using flat polishing base plates

Suggestion: If your polishing plate is not flat within these tolerances they should be lapped to these tighter tolerances.

Trouble Shooting for Polishing

| Symptom | Cause | Action |

|---|---|---|

| Coarse scratching | -Contamination on polishing pad | -Replace with a new pad |

| Tearing of pad |

-Too high a polishing force -Improper lubrication |

-Reduce polishing force -Dispense lubricant or abrasive more frequently |

| Excessive relief or edge rounding |

-Improper polishi -Excessive polishing times |

-Refer to polishing cloth

guide -Reduce polishing times and re-examine effectiveness of previous step |

Coarse Abrasive Polishing Pads (PSA)

(For Magnetic click here)

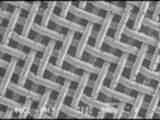

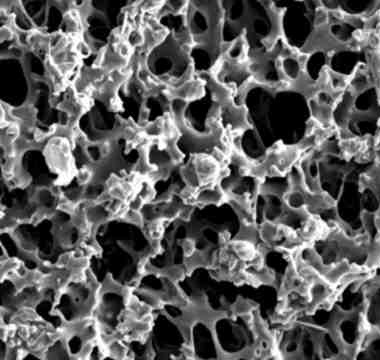

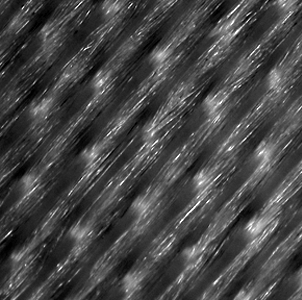

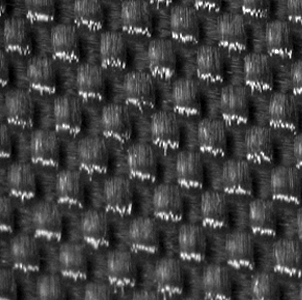

METAL MESH ABRASIVE CLOTH (with adhesive backing)

| Description | Diameter (inches) | Quantity | Catalog Number |

|---|---|---|---|

| CERMESH metal mesh cloth | 8 | 5/pkg. | CMESH-2008 |

| CERMESH metal mesh cloth | 9 | 5/pkg. | CMESH-2009 |

| CERMESH metal mesh cloth | 10 | 5/pkg. | CMESH-2010 |

| CERMESH metal mesh cloth | 12 | 5/pkg. | CMESH-2012 |

| CERMESH metal mesh cloth | 14 | 5/pkg. | CMESH-2014 |

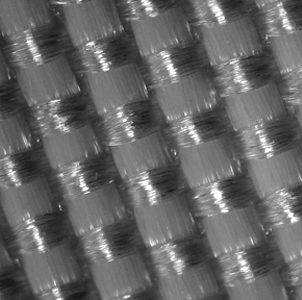

POLYPAD Polishing Pads (with adhesive backing)

| Description | Diameter (inches) | Quantity | Catalog Number |

|---|---|---|---|

| POLYPAD polishing pad w/ PSA | 8 | 10/pkg. | PP-6008 |

| POLYPAD polishing pad w/ PSA | 9 | 10/pkg. | PP-6009 |

| POLYPAD polishing pad w/ PSA | 10 | 10/pkg. | PP-6010 |

| POLYPAD polishing pad w/ PSA | 12 | 10/pkg. | PP-6012 |

| POLYPAD polishing pad w/ PSA | 14 | 10/pkg. | PP-6014 |

Intermediate Abrasive Polishing Pads (PSA)

TEXPAN Polishing Pads (with adhesive backing)

| Description | Diameter (inches) | Quantity | Catalog Number |

|---|---|---|---|

| TEXPAN polishing pad w/ PSA | 8 | 10/pkg. | TP-5008 |

| TEXPAN polishing pad w/ PSA | 9 | 10/pkg. | TP-5009 |

| TEXPAN polishing pad w/ PSA | 10 | 10/pkg. | TP-5010 |

| TEXPAN polishing pad w/ PSA | 12 | 10/pkg. | TP-5012 |

| TEXPAN polishing pad w/ PSA | 14 | 10/pkg. | TP-5014 |

Black CHEM 2 Polishing Pads (with adhesive backing)

| Description | Diameter (inches) | Quantity | Catalog Number |

|---|---|---|---|

| Black CHEM 2 polishing pad w/PSA | 8 | 10/pkg. | BC-8008 |

| Black CHEM 2 polishing pad w/PSA | 9 | 10/pkg. | BC-8009 |

| Black CHEM 2 polishing pad w/PSA | 10 | 10/pkg. | BC-8010 |

| Black CHEM 2 polishing pad w/PSA | 12 | 10/pkg. | BC-8012 |

| Black CHEM 2 polishing pad w/PSA | 14 | 10/pkg. | BC-8014 |

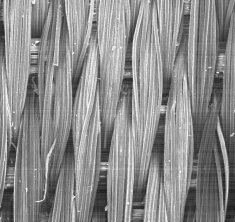

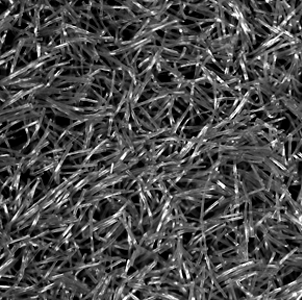

DACRON II Polishing Pads (with adhesive backing)

| Description | Diameter (inches) | Quantity | Catalog Number |

|---|---|---|---|

| DACRON II polishing pad w/ PSA | 8 | 5/pkg | D2C-3008 |

| DACRON II polishing pad w/ PSA | 9 | 5/pkg | D2C-3009 |

| DACRON II polishing pad w/ PSA | 10 | 5/pkg | D2C-3010 |

| DACRON II polishing pad w/ PSA | 12 | 5/pkg | DC2-3012 |

| DACRON II polishing pad w/ PSA | 14 | 5/pkg | D2C-3012 |

NYPAD Polishing Pads (with adhesive backing)

| Description | Diameter (inches) | Quantity | Catalog Number |

|---|---|---|---|

| NYPAD polishing pad w/ PSA | 8 | 10/pkg. | NY-3008 |

| NYPAD polishing pad w/ PSA | 9 | 10/pkg. | NY-3009 |

| NYPAD polishing pad w/ PSA | 10 | 10/pkg. | NY-3010 |

| NYPAD polishing pad w/ PSA | 12 | 10/pkg. | NY-3012 |

| NYPAD polishing pad w/ PSA | 14 | 10/pkg. | NY-3014 |

GOLD PAD Polishing Pads (with adhesive backing)

| Description | Diameter (inches) | Quantity | Catalog Number |

|---|---|---|---|

| GOLD PAD polishing pad w/ PSA | 8 | 10/pkg. | GP-4008 |

| GOLD PAD polishing pad w/ PSA | 9 | 10/pkg. | GP-4009 |

| GOLD PAD polishing pad w/ PSA | 10 | 10/pkg. | GP-4010 |

| GOLD PAD polishing pad w/ PSA | 12 | 10/pkg. | GP-4012 |

| GOLD PAD polishing pad w/ PSA | 14 | 10/pkg. | GP-4148 |

ATLANTIS Polishing Pads (with adhesive backing)

| Description | Diameter (inches) | Quantity | Catalog Number |

|---|---|---|---|

| ATLANTIS polishing pad w/ PSA | 8 | 5/pkg. | ATL-3008 |

| ATLANTIS polishing pad w/ PSA | 9 | 5/pkg. | ATL-3009 |

| ATLANTIS polishing pad w/ PSA | 10 | 5/pkg. | ATL-3010 |

| ATLANTIS polishing pad w/ PSA | 12 | 5/pkg. | ATL-3012 |

| ATLANTIS polishing pad w/ PSA | 14 | 5/pkg. | ATL-3014 |

Final Abrasive Polishing Pads (PSA)

MICROPAD Polishing Pads (with adhesive backing)

| Description | Diameter (inches) | Quantity | Catalog Number |

|---|---|---|---|

| MICROPAD polishing pad w/PSA | 8 | 10/pkg. | MP-9008 |

| MICROPAD polishing pad w/PSA | 9 | 10/pkg. | MP-9009 |

| MICROPAD polishing pad w/PSA | 10 | 10/pkg. | MP-9010 |

| MICROPAD polishing pad w/PSA | 12 | 10/pkg. | MP-9012 |

| MICROPAD polishing pad w/PSA | 14 | 10/pkg. | MP-9014 |

TRICOTE Polishing Pads (with adhesive backing)

| Description | Diameter (inches) | Quantity | Catalog Number |

|---|---|---|---|

| TRICOTE polishing pad w/ PSA | 8 | 10/pkg. | TRI-4008 |

| TRICOTE polishing pad w/ PSA | 9 | 10/pkg. | TRI-4009 |

| TRICOTE polishing pad w/ PSA | 10 | 10/pkg | TRI-4010 |

| TRICOTE polishing pad w/ PSA | 12 | 10/pkg | TRI-4012 |

| TRICOTE polishing pad w/ PSA | 14 | 10/pkg. | TRI-4014 |

NAPPAD Polishing Pads (with adhesive backing)

| Description | Diameter (inches) | Quantity | Catalog Number |

|---|---|---|---|

| NAPPAD polishing pad w/ PSA | 8 | 10/pkg. | NP-4008 |

| NAPPAD polishing pad w/ PSA | 9 | 10/pkg. | NP-4009 |

| NAPPAD polishing pad w/ PSA | 10 | 10/pkg | NP-4010 |

| NAPPAD polishing pad w/ PSA | 12 | 10/pkg | NP-4012 |

| NAPPAD polishing pad w/ PSA | 14 | 10/pkg. | NP-4014 |

MOLTEC 2 Polishing Pads (with adhesive backing)

| Description | Diameter (inches) | Quantity | Catalog Number |

|---|---|---|---|

| MOLTEC 2 polishing pad w/ PSA | 8 | 5/pkg | MT2-7008 |

| MOLTEC 2 polishing pad w/ PSA | 9 | 5/pkg | MT2-7009 |

| MOLTEC 2 polishing pad w/ PSA | 10 | 5/pkg | MT2-7010 |

| MOLTEC 2 polishing pad w/ PSA | 12 | 5/pkg | MT2-7012 |

| MOLTEC 2 polishing pad w/ PSA | 14 | 5/pkg | MT2-7014 |

FELT PAD Polishing Pads (with adhesive backing)

| Description | Diameter (inches) | Quantity | Catalog Number |

|---|---|---|---|

| FELT PAD polishing pad w/ PSA | 8 | 5/pkg | FP-8125-08 |

| FELT PAD polishing pad w/ PSA | 9 | 5/pkg | FP-8125-09 |

| FELT PAD polishing pad w/ PSA | 10 | 5/pkg | FP-8125-10 |

| FELT PAD polishing pad w/ PSA | 12 | 5/pkg | FP-8125-12 |

| FELT PAD polishing pad w/ PSA | 14 | 5/pkg | FP-8125-14 |

Magnetic Polishing Base for Adhesive backed Polishing Pads

| Description | Diameter (inches) | Quantity | Catalog Number |

|---|---|---|---|

| 8-inch magnetic base plate (PSA backed) | 8 | each | MAG-B08 |

| 10-inch magnetic base plate (PSA backed) | 10 | each | MAG-B10 |

| 12-inch magnetic base plate (PSA backed) | 12 | each | MAG-B12 |

| 14-inch magnetic base plate (PSA backed) | 14 | each | MAG-B14 |

| 8-inch Teflon coated base plate | 8 | each | MAG-P08 |

| 10-nch Teflon coated base plate | 10 | each | MAG-P10 |

| 12-inch Teflon coated base plate | 12 | each | MAG-P12 |