Metallographic Wafer Cutting Technical Information

Introduction

Precision wafer cutting is most commonly accomplished with diamond wafering blades, however for some materials the use of cubic boron nitride (CBN) is the more effiicient wafering blade. In addition, optimal wafer cutting is accomplished by maximizing the abrasive concentration and abrasive size, as well as choosing the most appropriate cutting speed and load. The following table provides the recommended parameters for precision wafering sectioning.

Precision wafer cutting is used for sectioning very delicate samples or for sectioning a sample to a very precise location. Precision wafering saws typically have micrometers for precise alignment and positioning of the sample, and have variable loading and cutting speed control. Typical precision wafering saws range in speeds from 50-1500 rpm or 300-3000 rpm. Higher speeds saws are required for sectioning very hard materials such as ceramics, heat treated steels and minerals.

|

|

|

| PICO 155 / PICO 155P Medium speed precision saw |

PICO 175 High speed precision saw |

PICO 200 Medium table feed saw |

Wafer Blade Selection Guidelines

| Material | Characteristic | Speed (rpm) | Load (grams) | Blade (grit/conc.) |

|---|---|---|---|---|

| Silicon substrate | soft/brittle | <300 | <100 | Fine/low |

| Gallium arsenide | soft/brittle | <200 | <100 | Fine/low |

| Boron composites | very brittle | 500 | 250 | Fine/low |

| Ceramic fiber composites | very brittle> | 1000 | 500 | Fine/low |

| Glasses | brittle | 1000 | 500 | Fine/low |

| Minerals | friable/brittle | >1500 | >500 | Fine/low |

| Alumina ceramic | hard/tough | >1500 | >500 | Medium / low |

| Zirconia (PSZ) | hard/tough | >3500 | >800 | Medium/low |

| Silicon nitride | hard/tough | >3500 | >800 | Medium/low |

| Metal matrix composites | >3500 | >500 | Medium/high | |

| General purpose | variable | Variable | Medium/high |

Precision Cutting Process Description

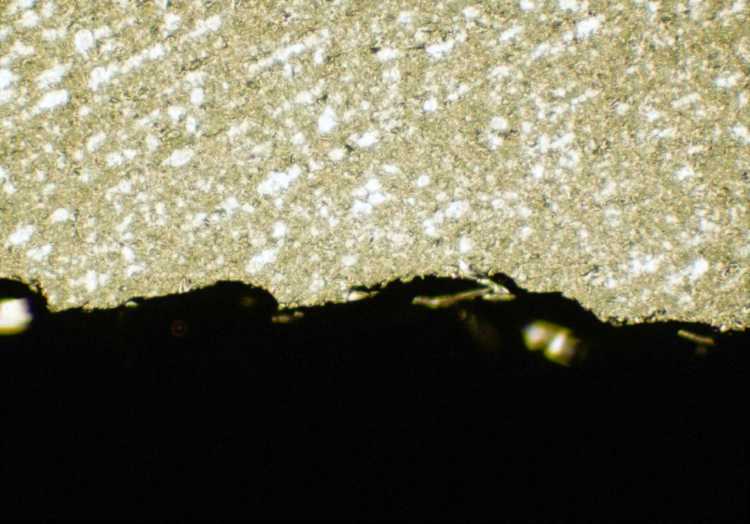

Perhaps the most important parameter for diamond sectioning is the abrasive size. Similar to grinding and polishing, finer abrasives produce less damage. For extremely brittle materials, finer abrasives are required to minimize and manage the damage produced during sectioning. Sectioning with a fine abrasive wafering blade is often the only way that a specimen can be cut so that the final polished specimen represents the true microstructure. Examples include: silicon computer chips, gallium arsenide, brittle glasses, ceramic composites, and boron/graphite composites.

|

|

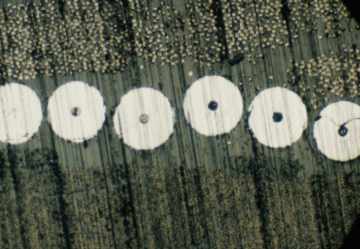

| Fine grit diamond wafering cut - graphite-boron composite | Medium grit diamond wafering cut - graphite-boron composite |

|

|

| Fine grit diamond wafering cut - silicon | Medium grit diamond wafering cut - silicon |

Precision Cutting Process Description

Wafer Sectioning - Sectioning with diamond wafering blades is most commonly used for delicate materials requiring a precise cut. The important parameters for sectioning with wafering blades are speed, load, diamond concentration and diamond size. The cutting speed and applied loads are a function of the material being cut. Most common diamond wafering is done between 50 rpm and 5000 rpm with loads varying from 10-1000 grams. Generally, harder specimens are cut at higher loads and speeds (e.g. ceramics and minerals) and more brittle specimens are cut at lower loads and speeds (e.g. electronic silicon substrates).

Several factors are important for choosing the appropriate wafering blade. These include: diamond concentration (low and high), diamond bond (metal plate), diamond size (fine or medium), blade diameter and blade thickness. The diamond concentration is important because it directly affects the load which is applied during cutting. For example, brittle materials such as ceramics require higher effective loads to section, whereas ductile materials such as metals require more cutting points. The result is that low concentration blades are recommended for sectioning hard brittle materials such as ceramics and high concentration blades are recommended for ductile materials containing a large fraction of metal or plastic.

The diamond bonding material can also significantly affect a blades cutting performance. Metal plated wafering blades require periodic dressing to maintain performance. Contary to popular thought, cutting performance does not decrease because of the diamond being "pulled-out" of the blade. In reality, the metal bond is primarily smearing over the diamond and "blinding" the diamond abrasive. With periodic dressing this smeared material is removed and the cutting rate restored. The following graph shows this effect on very hard to cut material such as silicon nitride without dressing the blade. Following dressing the sample once again was cut in 30 seconds.

Recommended Precision Cutting Procedures

- Condition the wafering blade with the appropriate dressing stick to remove previous cutting swarf and smeared metal from the wafering blade. A properly conditioned blade will cut faster and last longer. It is recommended that the dressing stick be mechanically applied to avoid twisting and chipping of the blade

- Clamp the specimen appropriately so that the sample does not shift during cutting

- For brittle materials clamp the specimen with a rubber pad to absorb vibration from the operation

- Begin the cut with a lower load to set the blade

- Orient the specimen so that the cut is through the smallest cross section

- Use largest appropriate blade flanges to prevent the blade from becoming distorted

- Reduce the load towards the end of the cut for brittle specimens (reduces fracturing at the end of the cut)

- Use the appropriate cutting fluid

Recommended Precision Cutting Procedures

Lubrication during abrasive cutting and diamond wafer cutting are required to minimize damage and to remove the cutting debris or swarf. For abrasive cutters the proper cutting fluid can have the added benefit of coating the cast iron bases and fixtures to eliminate corrosion and rusting of the cutter.

- Oil based diamond wafer cutting fluid - For diamond wafer cutting of metals an oil based cutting fluid is required to prevent the metal from coating the blade. Oil based cutting fluids therefore prolong the life and cutting efficiency of the diamond blade when cutting specimens requiring a high level of lubrication

- Water based diamond wafer cutting fluid - For ceramics, minerals, and composite type of samples a water based cutting fluid is recommended. Water based cutting fluids are easier to clean off the specimen, especially if the samples are porous.

Precision Cutting Trouble Shooting

| Symptom | Cause | Action |

|---|---|---|

| Chipped or broken blade |

-Improper blade dressing -Insufficient clamping of specimen -Too high an initial load |

-Use a mechanical dressing fixture -Secure specimen with a rubber pad -Reduce initial loading to set cutting kerf |

| Excessive blade wobble | -Too high a cutting load | -Reduce applied load and/or use larger diameter support flanges |

| Low cutting rates |

-Smeared material on the blade -Too low a cutting speed and/or load |

-Redress blade at <100 grams and <200 rpm -Increase cutting speeds and loads -Rotate specimen to minimize cutting area |

| Excessive specimen damage or chipping |

-Too large an abrasive -Excessive vibration |

-Use finer grit diamond blade -Secure specimen with rubber mounting pad |

| Burr formation on specimen at end of cut |

-Too high a load and/or speed at end of cut -Excessive vibration |

-Reduce speeds and loads to reduce cutting rate -Secure specimen with rubber mounting pads |

Precision Cutting Products

3-inch Diameter (76 mm) Wafering Blade, 1/2-inch (12.7 mm) Arbor

4-inch Diameter (102 mm) Wafering Blade, 1/2-inch (12.7 mm) Arbor

5-inch Diameter (127 mm) Wafering Blade, 1/2-nich (12.7 mm) Arbor

6-inch Diameter (153 mm) Wafering Blade, 1/2-inch (12.7 mm) Arbor

7-inch Diameter (178 mm) Wafering Blade, 1/2-inch (12.7 mm) Arbor

8-inch Diameter (203 mm) Wafering Blade, 1/2-inch (12.7 mm) Arbor

Electroplated Diameter Wafering Blade, 1/2-inch (12.7 mm) Arbor

CBN Wafering Blades, 1/2-inch (12.7 mm) Arbor

CBN/ Diamond Hybrid Wafering Blades, 1/2-inch (12.7 mm) Arbor

Cutting Fluid

MISCELLANEOUS

| Description | Quantity | Catalog Number |

|---|---|---|

| DIACUT Dressing sticks (medium grit) | each | DRES-0010 |

| Porometric mounting pads | 24/pkg. | PAD-0010 |