Metallographic Video Clips

MATERIALS PLUS COATING THICKNESS ANALYSIS VIDEO'S

MATERIALS PLUS COATING THICKNESS ANALYSIS VIDEO'S

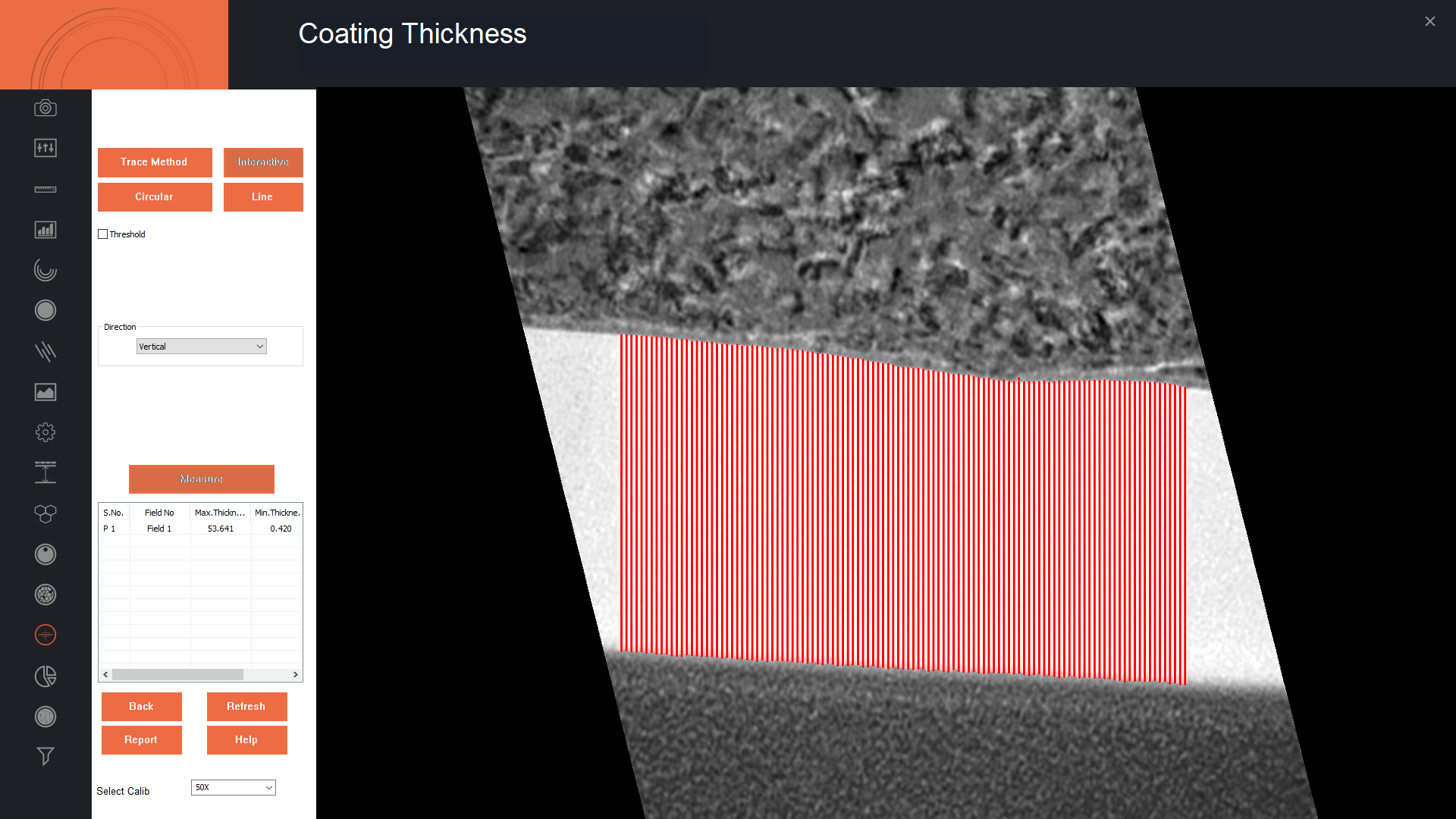

Four methods cover measurement of local thickness of metal and oxides through interactive or automated methods, These methods are available for straight, curve and circular thickness, The software follows ASTM E 1077 industrial method.

MATERIALS PLUS Coating Thickness

|

MATERIALS PLUS COATING THICKNESS SPECIFICATIONS

MATERIALS PLUS COATING THICKNESS SPECIFICATIONS

Measurement of coating thickness is very important for characterizing the performance of many materials. Such coatings can have very important wear, heat resistance, and corrosion resistant properties. ASTM B487 (Standard Test Method for Measurement of Metal and Oxide Coating Thickness by Microscopical Examination of Cross Section) describes the recommended acceptance testing procedures for measuring coating thickness.

As with other metallographic analysis, proper specimen preparation is required to obtain a meaningful quantitative number. In general, the specimens need to be mounted, polished and etched so that the cross section is perpendicular to the coating as to avoid any geometrical errors in measuring the coating thickness. It is important that the surface be flat across the entire sample so that the boundaries are sharply defined. The cross section should also be prepared to eliminate deformation, smearing and other polishing artifacts.

| Feature | Specification |

|---|---|

| Coating Thickness |  |

| Testing Standard(s) | ASTM B487 |

| Example Procedure |