Step-by-Step Guide to Aluminum Sample Preparation

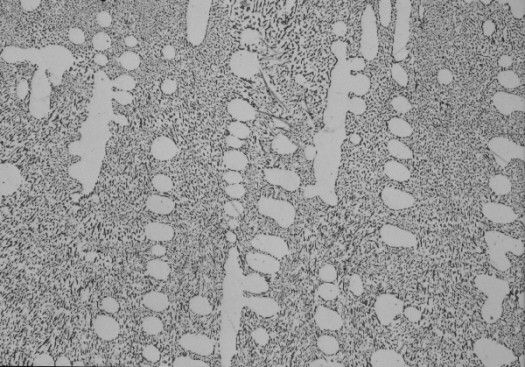

Aluminum and its alloys are foundational in aerospace, automotive, and structural engineering. Their low density, corrosion resistance, and mechanical versatility demand precise metallographic preparation for effective microstructural analysis. This comprehensive guide provides expert-recommended procedures for preparing aluminum specimens.

Key Challenges in Aluminum Preparation

- Smearing and grain pull-out during preparation

- Oxide disruption and surface contamination

- Maintaining microstructural integrity

- Avoiding abrasive embedding

- Supporting high-resolution phase delineation

Technical Considerations

- Aluminum's low melting point (660°C) requires careful temperature control

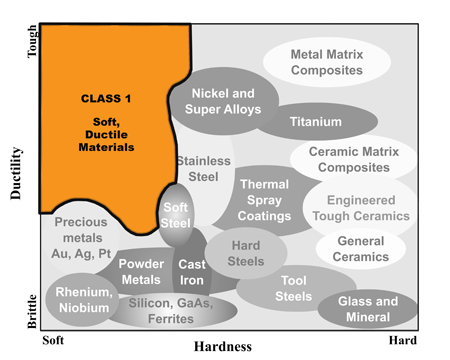

- Soft nature (typically 20-100 HV) demands gentle preparation

- High thermal conductivity necessitates proper cooling

- Rapid oxidation requires immediate post-preparation protection

Want to keep track of your preparation procedures? Save your workflow procedures on materialsprep.com