Step-by-Step Guide to Stainless Steel Sample Preparation

Stainless steels--ranging from austenitic and ferritic to martensitic and duplex grades--are used across critical industries such as medical, food processing, petrochemical, and power generation. Their corrosion resistance, phase stability, and microstructural complexity require meticulous metallographic preparation. This guide outlines the best practices for preparing stainless steel specimens for reliable microscopic analysis.

- Retention of deformation zones and work-hardened layers

- Differential etching across phase boundaries

- Carbide pull-out or smearing in martensitic types

- Phase transformation during polishing (especially in duplex)

- Intergranular corrosion artifacts from improper prep

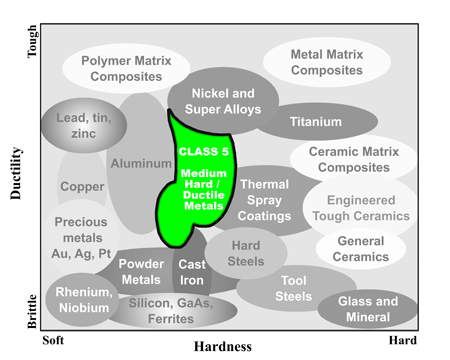

- Hardness range varies significantly by grade (150–700 HV)

- High alloy content requires controlled etching for phase visibility

- Proper cooling during grinding prevents thermal damage

- Electrolytic polishing and etching often recommended for best contrast

Want to keep track of your preparation procedures? Save your workflow procedures on materialsprep.com