Metallographic Compression Mounting Information

Compression mounting is a very useful mounting technique which can provide better specimen edge retention compared to castable mounting resins. Compression mounting resins are available in different colors and with various fillers to improve hardness or conductivity.

Several compression mounting characteristics include:

- Convenient means to hold the specimen

- Provides a standard format to mount multiple specimens

- Protects edges

- Provides proper specimen orientation

- Provides the ability to label and store the specimens

Compression mounts are quick and easy to produce, requiring several minutes to cure at the appropriate mounting temperature. Most of the time required in compression mounting occurs during the heating and cooling cycles. When choosing a compression mounting machine, the most important features include its maximum heating temperature and how intimately the heater and water cooler are connected to the mold assembly. The better compression mounting machines have heaters which can reach temperatures of at least 200°C ( 450°F). For faster turn around time, water cooling is essential.

Compression mounting resins include:

- Phenolic Resins (standard colors are black, red and green)

- Acrylic Resins (clear)

- Diallyl Phthalate Resins (blue and black)

- Epoxy Resins (glass-filled)

- Conductive Resins (phenolics with copper or graphite filler)

|

|

|

|

Compression Mounting Resin Properties

There are a variety of compression mounting materials. The two main classes of compression mounting materials are thermoset and thermoplastics. Thermoset resins require heat and pressure to cross-link the polymer and the reaction is irreversible. Thermoplastic, on the other hand, can theoretically be remelted.

See the following tables for more specific information for the various compression mounting resins.

| Phenolics | Acrylics | Epoxy (glass filled) |

Diallyl Phthalates |

|

|---|---|---|---|---|

| Cost | Low | Moderate | Moderate | Moderate |

| Ease of use | Excellent | Moderate | Good | Good |

| Availability of colors | Yes | No | No | Yes |

| Cycle times | Excellent | Moderate | Good | Good |

| Edge retention | Fair | Good | Excellent | Excellent |

| Clarity | None | Excellent | None | None |

| Hardness | Low | Medium | High | High |

TIP: Compression mounting at higher then the recommended minimum temperature generally improves the properties of the mount.

TIP: A useful tip for marking or identifying a specimen is to mold the label inside of the mount. If the entire mount is an acrylic, just place the label on top the mount and cover it with a little acrylic powder. To label other compression mounting resins, add a thin layer of acrylic over the other mounting material and then position the label on this layer. Finish off the mount with another layer of acrylic.

| Phenolics | Acrylics | Epoxy (glass filled) |

Diallyl Phthalates |

|

|---|---|---|---|---|

| Form | Granular | Powder | Granular | Granular |

|

Specific gravity (gm/cm3) |

1.4 | 0.95 | 1.75-2.05 | 1.7-1.9 |

| Colors | Black, Red, Green, Orange, White | Clear | Black | Blue |

| Shrinkage (compression)(in/in) | 0.006 | 0.001-0.003 | 0.001-0.003 | |

|

Coefficient of Linear Thermal Expansion (in/in/°C 10-6) |

50 | 28 | 19 | |

|

Chemical resistance |

Glycol, petrochemicals, solvents, some acids and bases | Alcohol, dilute acids & alkalies, and oxidizers | Solvents, acids, alkalies | Solvents, acids, alkalies |

| Molding temperature | 200°C (392°F) | 220°C (428°F) | 200°C (392°F) | 200°C (392°F) |

|

Hardness |

Rockwell M63 | Barcol 72 | ||

|

Curing time |

8-10 minutes | 12-15 minutes | 8-10 minutes | 8-10 minutes |

Note Phenolics: -In general, phenolics are used because of their relatively low cost. In addition, phenolics are available in a variety of colors.

TIP: Use different color phenolics to color code jobs, specimens types, or for different testing dates. For example, changing the phenolic color each month will show which samples or jobs are getting old.

TIP: If the color dye in the mount bleeds out when rinsing with an alcohol, this is an indication that the mount was not cured either at a high enough temperature or for the proper length of time.

Acrylics: The main application for compression mounting acrylics is based on their excellent clarity. This is particularly important for locating a specific feature within the specimen mount.

TIP: A common problem, know as the “cotton ball” effect, can occur with thermoplastic resins if they are heated to too high a temperature too fast so a liquid layer forms around the unmelted resin giving it the appearance of a cotton ball in the middle of the mount. To avoid this problem mount at a lower temperature (120-140°C), however, to correct this problem after the fact, simply put the mount back into the mounting press and either increase the time. Eventually this will eliminate the “cotton ball.”

Epoxies / Diallyl Phthalates: Glass-filled epoxies and diallyl phthalates are compression mounting resins used to provide a harder mounting support edge next to the specimen. These resins are commonly used to support the edges of coatings, heat treated samples and other specimens requiring better flatness. The following figure shows the polished interface between a glass-filled epoxy and tungsten carbide specimen. Note that there is no noticeable gap between the specimen and the mounting material, therefore showing that glass-filled epoxies provide excellent support to the specimen edge even for extremely hard specimens.

Polished edge for tungsten carbide mounted in glass-filled epoxy.

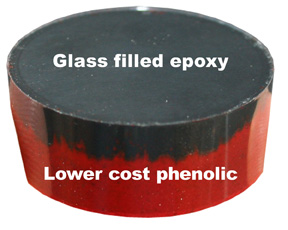

TIP: Epoxies (glass-filled) and diallyl phthalates are significantly more expensive then phenolic and acrylics. In order to reduce the cost of these mounts, they can be laminated with a lower cost mounting compound such as a phenolic. The technique is to place a sufficiently thick enough layer of the glass-filled epoxy or diallyl phthalate around the specimen in order to compensate for any grinding loss. The rest of the mount can then be supported with a lower cost compression mounting compound such as a phenolic. Red phenolics are used frequently for this technique.

Specialized Compression Mounting Resins: - With the addition of fillers such as graphite or copper, the compression mounting compounds can be made conductive. Conductive mounts are used in scanning electron microscopes (SEM) to prevent the specimen from building up a charge. Conductive mounts are also used for specimens requiring electrolytic etching or polishing.

Recommended Compression Mounting Procedure

- Clean specimens to remove cutting and handling residues

- Remove debris from mold assembly

- Apply thin coat of mold release compound to mold assembly

- Raise mold ram to up position

- Center specimen on ram

- Lower ram assembly

- Pour predetermined amount of resin into mold

- Clean and remove any excess resin from around the mold assembly threads

- Lock mold assembly cover

- Slowly raise ram into up position

- Apply recommended heat and maintain pressure for specified period of time

- Cool to near room temperature

- Remove mounted specimen

- Clean mold and ram assembly

Compression Mounting Trouble Shooting

| Symptom | Cause | Action |

|---|---|---|

| Large bubbles in acrylic resins | Curing temperature too high or mounting press has insufficient mounting pressure | Reduce temperature (120-140°C) and increase mounting pressure |

| Soft surfaces on mount | Mount did not completely polymerize because of polymer incompatibility with mold release or oil on the specimen surface | Clean specimen and mounting machine to remove incompatible coatings. Use a compatible mold release |

| Voids or cracks | High internal stress due to overly rapid cooling | Allow mounts to cool more slowly and longer |

| Haze around specimen (acrylic mounts) | Specimen contains moisture

Specimens contain copper or some other polymerization retarding alloy |

Use a desiccator or low

temperature oven to dry specimen Coat specimens with an appropriate lacquer before mounting |

| Phenolic dye leaching out with alcohol rinsing | Insufficient mounting temperature | Increase mounting temperature or service check heater element |

| Distortion or cracking of specimen | Autoclave pressure is too great for the specimen | Reduce mounting pressure or use a castable epoxy resin |

Product Descriptions

Phenolic Mounting Resin

TRANSACRYLIC Compression Mounting Resin

| Description | Quantity | Catalog Number | Product Image |

|---|---|---|---|

| TRANSACRYLIC Resin powder (transparent) | 5 lbs (2.3 kg) | CM-2101A-5 |  |

| TRANSACRYLIC Resin powder (transparent) | 25 lbs (11.4 kg) |

CM-2101A-25 |

EPOXY (Glass Reinforced) Compression Mounting Resin

Diallyl Phthalate Compression Mounting Resin

Conductive Mounting Resin

Miscellaneous

| Description | Quantity | Catalog Number | Product Image |

|---|---|---|---|

| 30 ml measuring scoop | 30 ml | MS-1000-30 |  |

| Mold release | 8 oz (0.24l) 16 oz (0.47l) |

MR-1000-08 MR-1000-16 |

|