Etchants in Metallography

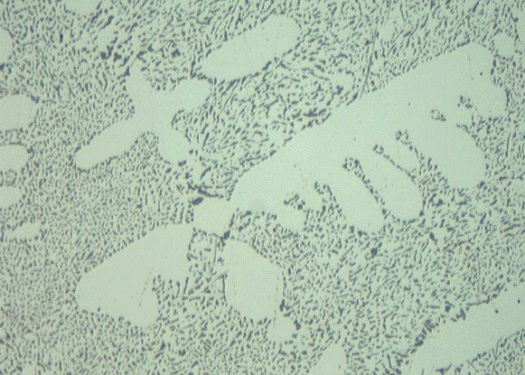

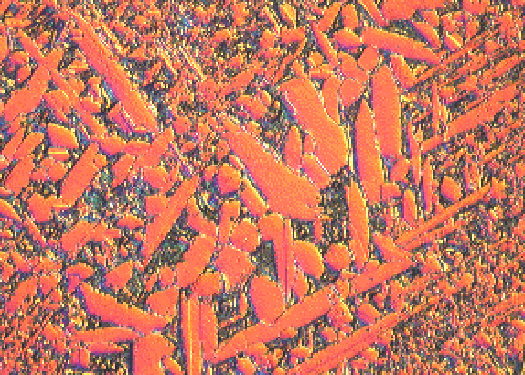

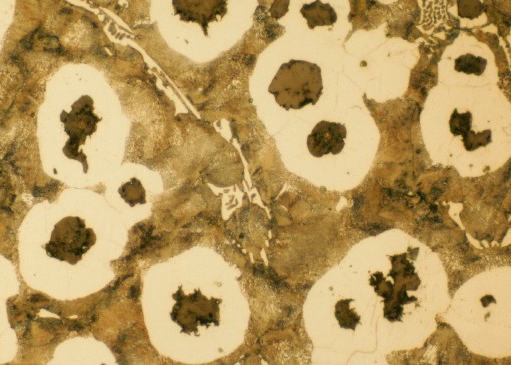

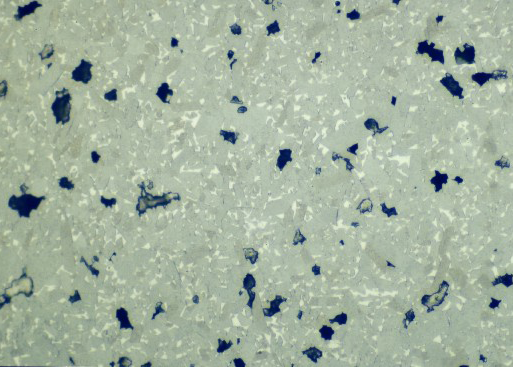

Etchants are chemical solutions used in metallographic sample preparation to reveal the microstructure of metals, alloys, and ceramics. By selectively attacking specific constituents within a polished sample, etchants expose grain boundaries, phase regions, precipitates, and structural anomalies that are otherwise invisible under a microscope. Proper etching is critical for quality control, failure analysis, and research across a wide range of materials. Browse our full selection of high-quality etchants and reagents.

Why Etching Matters:

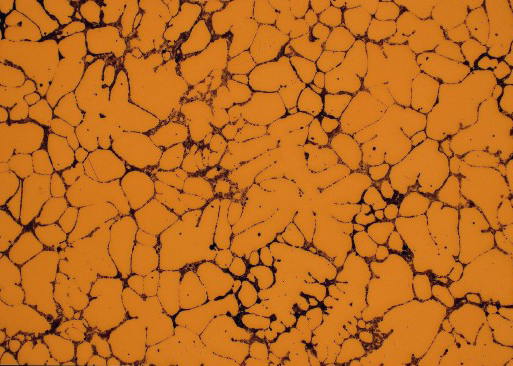

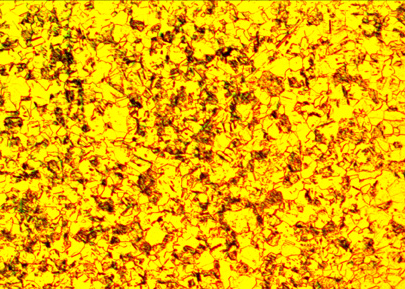

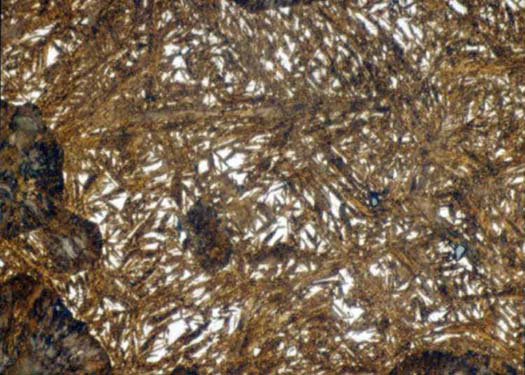

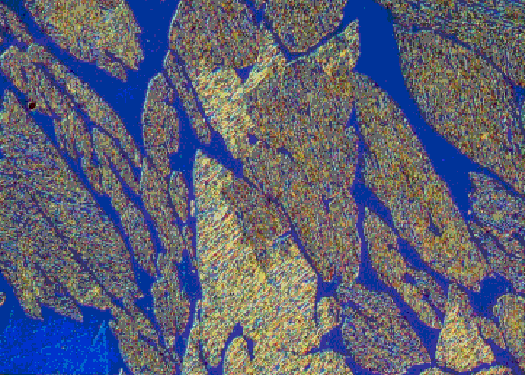

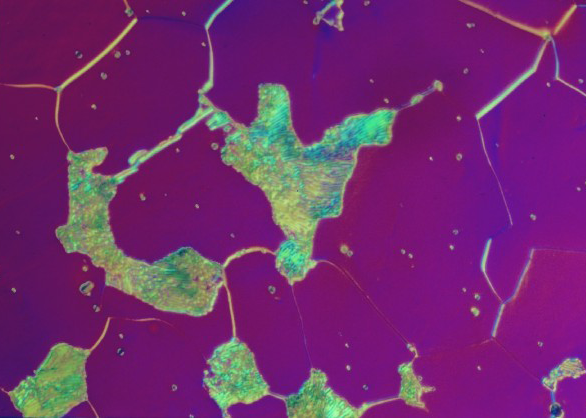

- Reveal Microstructures: Etchants unveil the grain structure, shape, size, and distribution of phases critical to understanding material properties.

- Differentiate Phases: Selective chemical reactions make it possible to distinguish ferrite from pearlite, martensite from austenite, or carbide networks from base matrices.

- Improve Optical Contrast: Etched surfaces enhance contrast and clarity for optical or electron microscopy, aiding accurate imaging and interpretation.

- Support Failure Analysis: Etching helps identify structural discontinuities, segregation zones, and heat-affected areas in fractured or worn components.