Metallographic semi-automated polishing machines are available with individual/single specimen loading or with a fixed central holder. The main advantage for using a central force holder is that the overall specimen flatness is better. The primary advantages for individual specimen holders are fewer required grinding/polishing steps and the ability to repolish samples without the need to re-planarize the specimens.

Key Points

- Individual Force: The force is applied to each sample individually. The main advantage is the elimination of the planar grinding steps. The primary disadvantage is that the specimen plane is not fixed in a rigid position during grinding and can result in loss of flatness across the specimen.

- Central Force: Specimens are locked into a rigid position or fixed plane so they cannot rock during sample preparation, especially the planar or coarser grinding steps. The advantage is better flatness across all specimen mounts, but 1-2 more planar grinding steps are required using coarser abrasives.

Advantages

| Individual |

Central |

| Reduced number of preparation steps and lower cost for consumables |

Flatter specimens |

| Sample can be re-polished without having to planarize specimens in the holder |

Specimens can be polished in both the contra and complementary head/base directions |

Disadvantages

| Individual |

Central |

| Can result in loss of flatness across the specimen if heavy duty grinding is required |

Minimum of 3-sample are required in the holder |

| It is recommended that the grinding and polishing steps only be done at matching head and base speeds with the rotation being in the same direction |

Typically requires 1-3 additional coarser grinding steps to planarize all specimens |

|

Additional grinding steps increase both consumables cost and total preparation time |

|

Coarser grinding can result in more surface and subsurface damage to the specimen |

|

Need to planarize specimens again if they are removed from the fixed holder |

Preparation Requirements

| Step |

Individual |

Central |

| Planar Grinding |

n/a |

120, 240 grit SiC |

| Rough Grinding |

360, 600 grit SiC |

360, 600 grit SiC |

| Fine Grinding |

800, 1200 grit SiC |

800, 1200 grit SiC |

| Intermediate Polishing |

1 micron polycrystalline diamond on a woven pad |

1 micron polycrystalline diamond on a woven pad |

| Final Polishing |

0.05 micron NANOMETER alumina on a napped pad |

0.05 micron NANOMETER alumina on a napped pad |

Individual Force Automated Polishing

Individual Force: Individual specimen force can be applied using the Quick Release Chuck system by screwing down the outside of the coupler so as to lock the specimen mounting plate into a rigid plane. This set-up allows for the individual holder to be removed and cleaned. This holder also eliminates the need to replane the samples if they are removed from the holder.

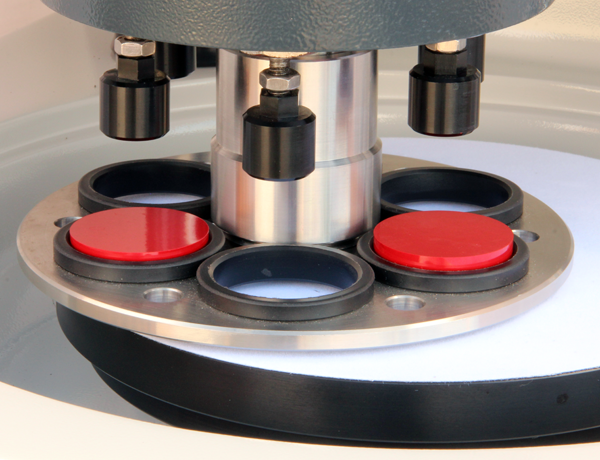

- Individual Force Pistons in the off position.

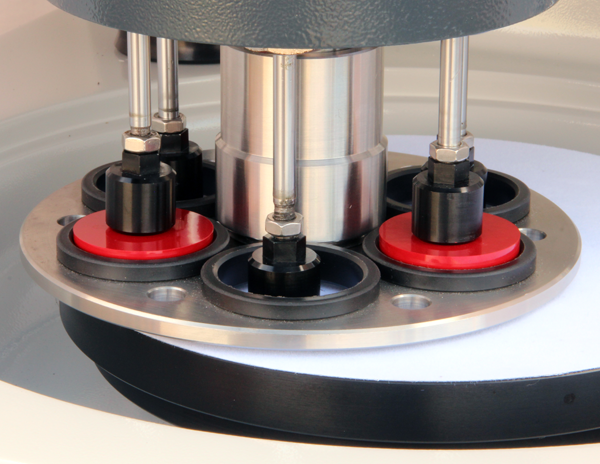

- Individual Force Pistons in the on position - Force is applied to each specimen individually.

Central Force Automated Polishing

Central Force: The individual pistons apply the polishing force to the landing pads and push down the holder through the spring loaded central male coupler (patent pending). For central polishing a minimum of three samples locked into the holder is required; however, flatness is then fixed over all the mounted specimens.

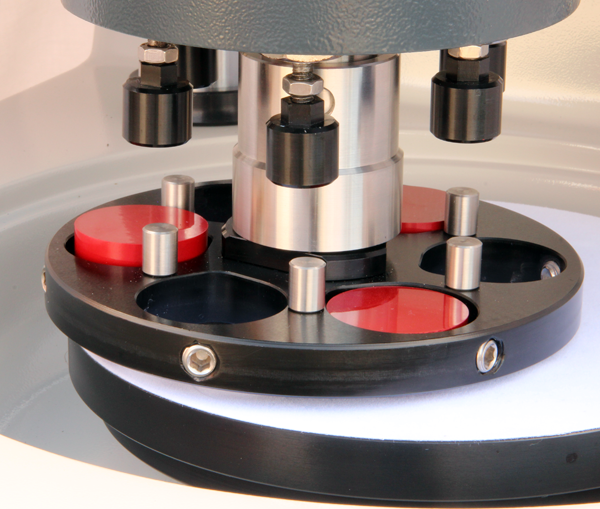

- Central Force in the off position.

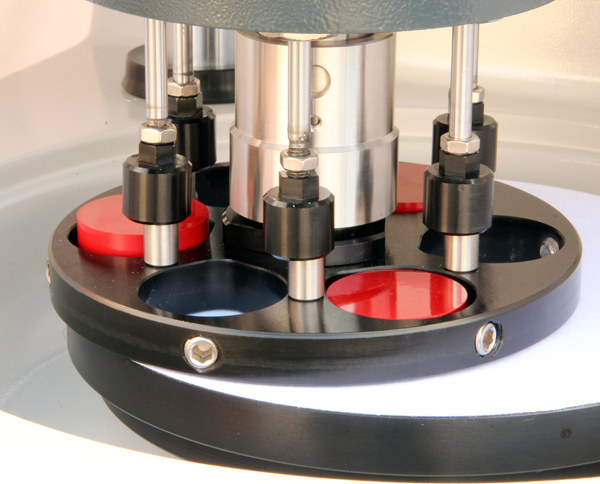

- Central Force in the on position - Force is applied to the rigid specimen sample holder.

Autopolishing Heads for Individual and Dual Central / Individual Polishing