Metallographic Hastelloy Etchants

Etching Hastelloy is difficult due to the anti-corrosive nature of these alloys. Hastelloy's are high temperature corrosion resistant superalloys that are primarily nickel alloys containing various amount of molybdenum, chromium, colbalt, iron, copper, manganese, titanium, zirconium, aluminum, carbon and tungsten.

CAUTION: Safety is very important when etching. Be sure to wear the appropriate protective clothing and observe all WARNINGS on chemical manufacuters SDS (Safety Data Sheets). Also review the COMMENTS and CONDITIONS Section for each etchant.

Sample Preparation:

Hastelloy's must be properly prepared to reveal the true metallographic microstructure. A number of recommended procedures can be found at the following links:

Recommended Etchants

| Etchant | Conc. | Conditions | Comments |

|---|---|---|---|

| Adlers Etchant: Ferric chloride Copper ammonium chloride Hydrochloric acid Distilled water |

45 gm 9 gm 150 ml 75 ml |

Immerse for several seconds. | A very effective etchant for Hastelloy metals |

|

Wecks Nickel Reagent Potassium Permanganate Sodium Hydroxide Distilled water |

10 grams 2.5 grams 250 ml |

Immersion or swabbing etch at 20 degrees Celsius |

Used for etching nickel-based alloys, revealing grain structure and other microstructural details. |

|

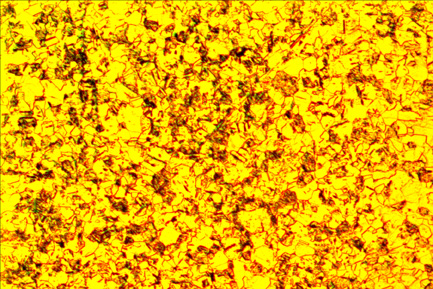

Hastelloy etched with Adlers etchant, Mag. 200X (DIC). |