Brass (copper-zinc alloys)

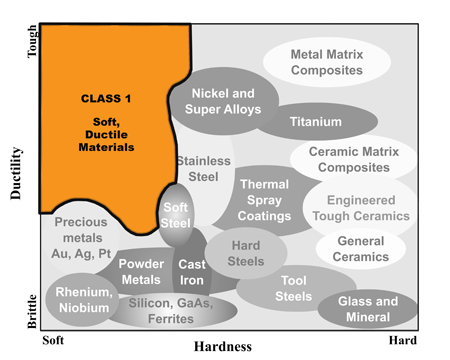

Specimen Preparation (Class 1 Procedures)

|

Brass is a copper-zinc alloy, whereas bronze is a copper-tin alloy. Brass is stronger than copper and has a higher malleability then either copper and zinc. Brass is also a good conductor of heat, has excellent acoustic properties and is generally resistant to corrosion in salt water. Brass is commonly rolled and extruded; however, these processes also work harden and can be quanitified by metallographic analysis.

SECTIONING

MAXCUT Abrasive blade (Cat. No. MAX-C or MAX-I series)

MOUNTING

Compression Mounting with Phenolic, Epoxy or Diallyl Phthalate compression mounting resins

POLISHING

*Required for central polishing force. Click here for more information on central vs. individual polishing force polishing.

|

| 70-30 Brass, 200X (B.F.), Etchant H2O2 / NH4OH |

|

| 70-30 Brass cold rolled, 200X (B.F.),

Etchant H2O2 / NH4OH |

|

| 70-30 Brass deep rolled, 200X (B.F.),

Etchant H2O2 / NH4OH |

ETCHING

Common Etchants

CAUTION:Safety is very important when etching. Be sure to wear the appropriate protective clothing and observe all WARNINGS on chemical manufacuters SDS (Safety Data Sheets). Also review the COMMENTS and CONDITIONS Section for each etchant.