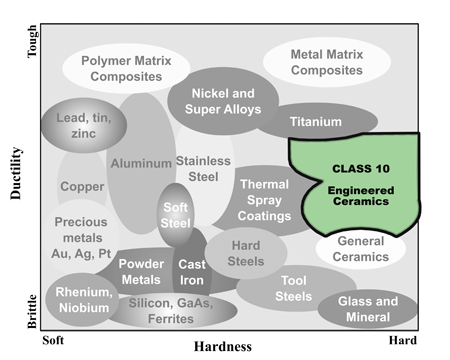

SIALON Engineering Ceramic

Specimen Preparation (Class 10 Procedures)

|

SIALON ceramics is a machineable ceramic and is thus fairly easy to prepare for microstructural evaluation. The primary concern is to minimize excessive cracking during cutting and initial grinding through the use of the appropriate diamond wafering blade and with semi-fixed abrasives on a metal mesh cloth. Polishing with CMP (chemical mechanical polishing) techniques is also a very effective way to remove surface and subsurface damage to the specimen.

SECTIONING

Diamond Wafering blade - medium grit / low concentration

MOUNTING

Castable Mounting with Epoxy or Acrylic resins.

POLISHING

*Required for central polishing force. Click here for more information on central vs. individual polishing force polishing.

|

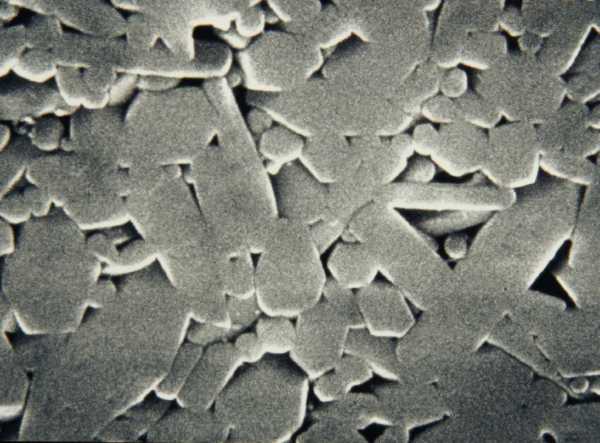

| SiAlON ceramic, etched in molten KOH, Mag 20,000X |

Common Etchants

CAUTION:Safety is very important when etching. Be sure to wear the appropriate protective clothing and observe all WARNINGS on chemical manufacuters SDS (Safety Data Sheets). Also review the COMMENTS and CONDITIONS Section for each etchant.