|

|

|

Neodymium

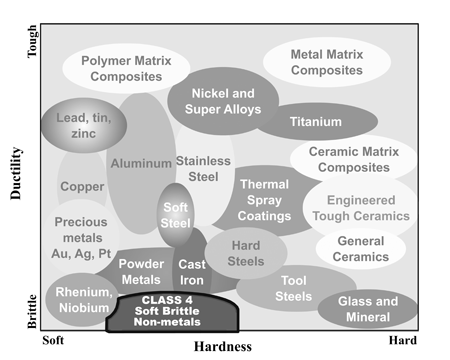

Specimen Preparation (Class 4 Procedures)

|

|

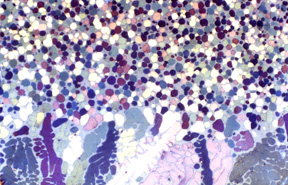

Neodymium is a rare earth metal which has some very interesting properties. The applications for neodymium include magnets (strongest permanent magnets known), colorant for welder's glasses, cyrocoolers (high specific heat capacity), light filters, fertilizers, and for lasers.

SECTIONING

MAXCUT Abrasive blade (Cat. No. MAX-I series)

MOUNTING

Compression Mounting with Phenolic, Epoxy or Diallyl Phthalate compression mounting resins

POLISHING

*Required for central polishing force. Click here for more information on central vs. individual polishing force polishing.

|

| Neodymium-Aluminum-Titanium casting, (polarized light). |

ETCHING

Common Etchants

CAUTION:Safety is very important when etching. Be sure to wear the appropriate protective clothing and observe all WARNINGS on chemical manufacuters SDS (Safety Data Sheets). Also review the COMMENTS and CONDITIONS Section for each etchant.