CLASS 3 Lower Ductility Metals

| CLASS 3 Lower Ductility Metals |

| Powder Metallurgy | Cast Irons |

|---|---|

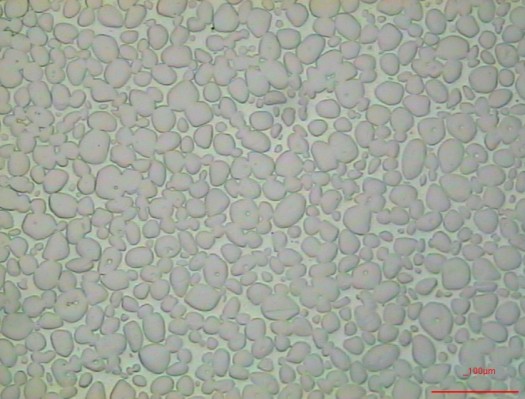

Sintered Iron |

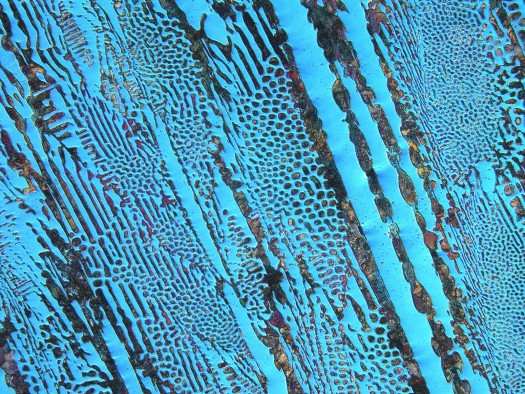

Cast Irons |

Tungsten |

White Metal |

| CLASS 3 Lower Ductility Metals |

| Powder Metallurgy | Cast Irons |

|---|---|

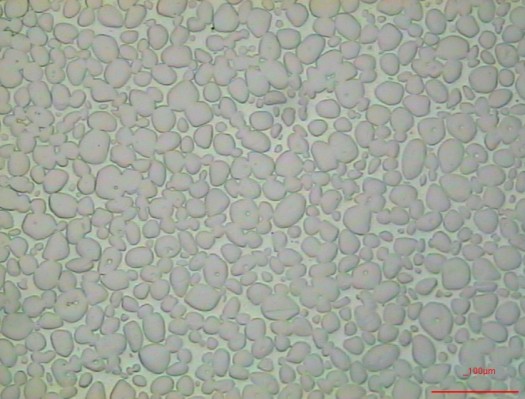

Sintered Iron |

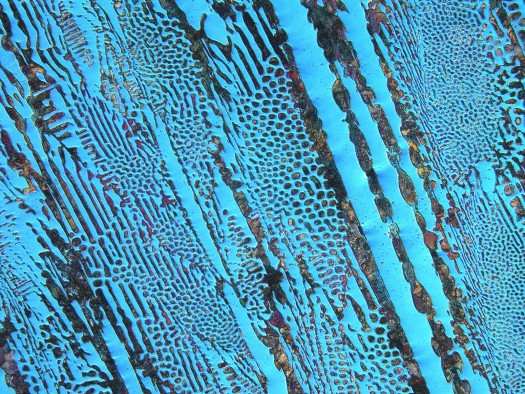

Cast Irons |

Tungsten |

White Metal |