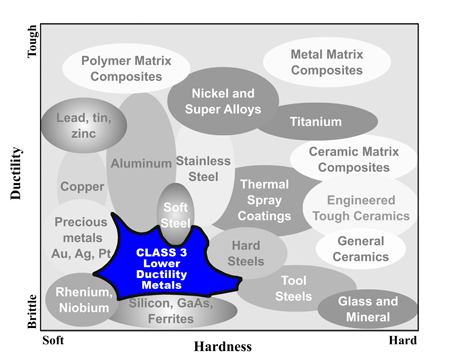

Sintered Iron

Specimen Preparation (Class 3 Procedures)

|

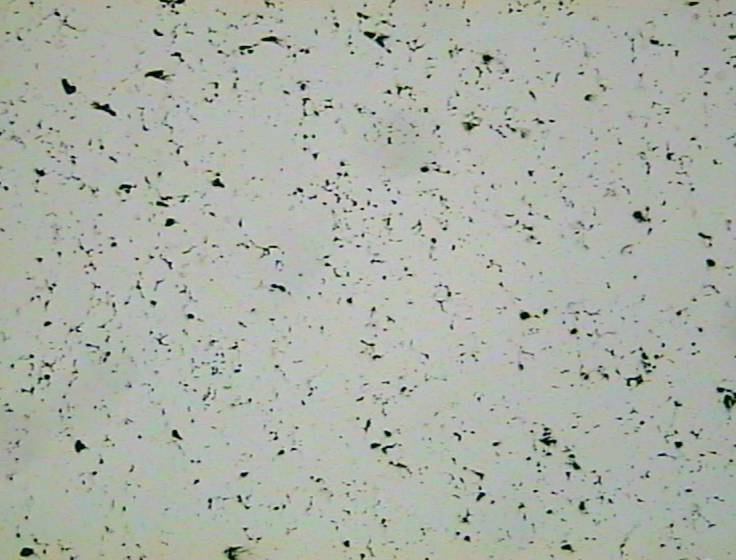

Powder metallurgy is a very useful manufacturing process for parts designed with hard-to-machine geometries. The process includes pressing a metal powder into the rough shape and then sintering it just below the melting temperature of the alloy.

The metallographic specimen preparation of powder metallurgy samples is affected by the specimen’s composition, packing and sintering conditions. Microstructural features of interest include: porosity, grain size, inclusions and orientation of voids. Proper metallurgical preparation takes into account that the microstructure may be porous and perhaps somewhat brittle due to inadequate sintering conditions.

SECTIONING

MAXCUT Abrasive blade (Cat. No. MAX-E or MAX-I series)

MOUNTING

Castable mounting with epoxies or acrylics using vacuum impregnation

POLISHING

*Required for central polishing force. Click here for more information on central vs. individual polishing force polishing.

|

| Sintered Iron, Mag. 100x (B.F.), as polished) |

ETCHING

Common Etchants

CAUTION:Safety is very important when etching. Be sure to wear the appropriate protective clothing and observe all WARNINGS on chemical manufacuters SDS (Safety Data Sheets). Also review the COMMENTS and CONDITIONS Section for each etchant.