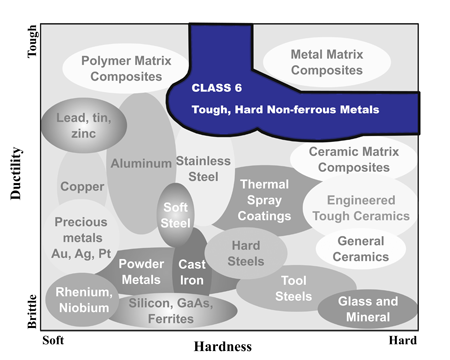

Nickel Hastelloy Superalloy

Specimen Preparation (Class 6 Procedures)

|

Temperature and corrosion resistant materials such as Hasteloy Nickel Based Superalloys are prepared mostly with standard metallographic techniques. However, the results can be significantly improved by using finely graded CMP (chemical mechanical polish) polishing solutions on a high napped polishing pad.

SECTIONING

MAXCUT Abrasive blade (Cat. No. MAX-E or MAX-VHS series)

MOUNTING

Compression Mounting with Phenolic, Epoxy or Diallyl Phthalate compression mounting resins

POLISHING

*Required for central polishing force. Click here for more information on central vs. individual polishing force polishing.

|

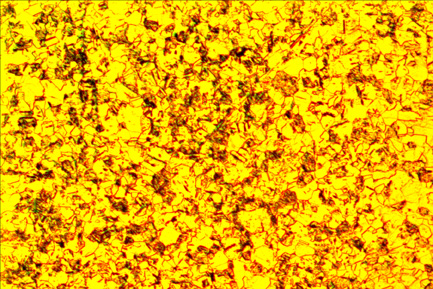

| Hastelloy etched with Adlers etchant, Mag. 200X (DIC). Composition: Molybdenum: 8-10%, Chromium: 20.5-23%, Iron: 17-20%, Tungsten: 0.2-1%, Cobalt: 0.5-2.5%, Carbon: 0.05-.015%, Silicon: 1%, Manganese: 1%, Boron: 0.01%, Phosphorus: 0.04%, Sulfur: 0.03%, Nickel: Remainder |

ETCHING

Common Etchants

CAUTION:Safety is very important when etching. Be sure to wear the appropriate protective clothing and observe all WARNINGS on chemical manufacuters SDS (Safety Data Sheets). Also review the COMMENTS and CONDITIONS Section for each etchant.