Multilayer BaTiO3 Ceramic Capacitor

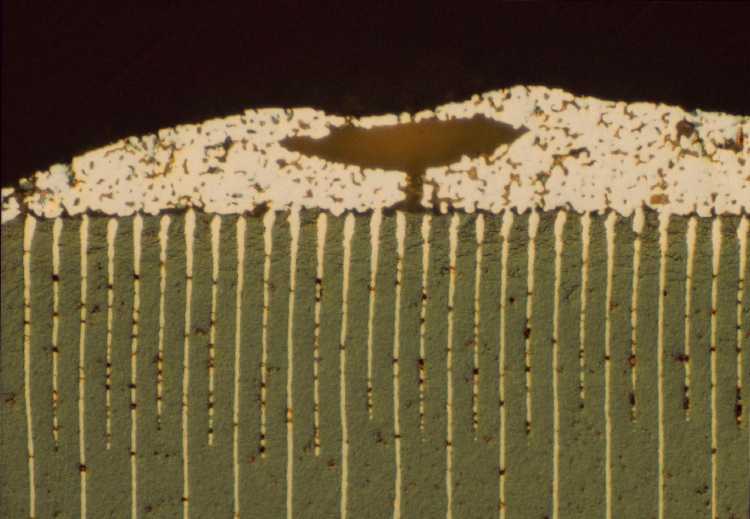

Specimen Preparation (Class 4 Procedures)

|

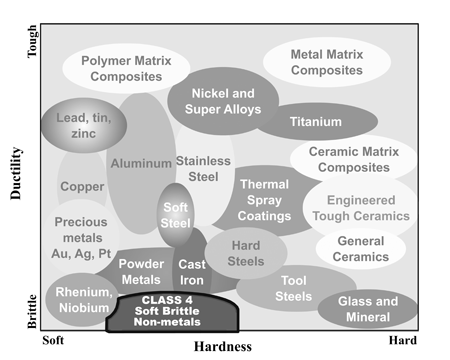

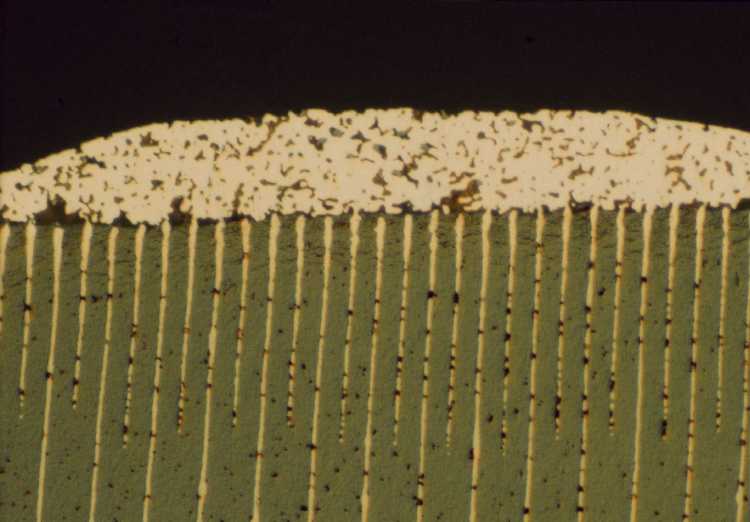

Ceramic capacitors are typically very small, inexpensive devices used in cell phones, MP3 players, computers and other electronic products. MLC devices are constructed of alternating layers of metal and ceramic, with the ceramic material acting as the dielectric.

Microstructural analysis of a BaTiO3 ceramic capacitor includes looking for missing metal layers, as well as for examining for any gaps and voids in the ceramic substrate. Microstructural preparation of multilayer BaTiO3 ceramic capacitors requires minimizing polishing relief and damage to the coating or ceramic substrate. This is accomplished by filling the existing voids with a castable resin under vacuum and then curing at a higher pressure. Initial grinding with alumina lapping films is required to open up the capacitor, as well as to minimize microstructural damage. Rough and final polishing are recommended on low napped woven polishing pads using diamond and colloidal silica, respectively.

SECTIONING

Not required

MOUNTING

Castable epoxy or acrylic resins

POLISHING

*Required for central polishing force. Click here for more information on central vs. individual polishing force polishing.

|

| BaTiO3 Multi-layer Ceramic Capacitor |

|

| BaTiO3 Multi-layer Ceramic Capacitor with void in metal layer |

ETCHING

Common Etchants

CAUTION:Safety is very important when etching. Be sure to wear the appropriate protective clothing and observe all WARNINGS on chemical manufacuters SDS (Safety Data Sheets). Also review the COMMENTS and CONDITIONS Section for each etchant.