Mullite Ceramic

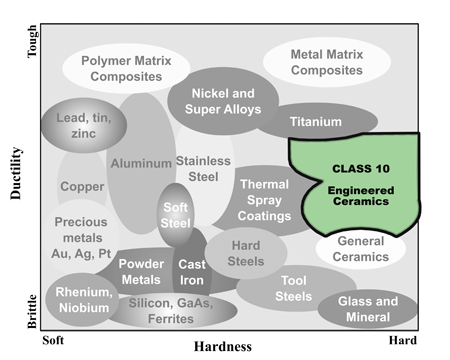

Specimen Preparation (Class 10 Procedures)

|

The preparation of hard/brittle/porous ceramic materials is not especially difficult with a few simple preparation tricks. First, to minimize grain pull-out which may be falsely characterized as porosity sectioning damage must be minimized. This is accomplished by sectioning with the appropriate diamond wafering blade and using the finest practical abrasive for initial grinding. Planar grinding is best achieved with the use of as small a diamond abrasive as possible on a metal mesh cloth. Note there is a trade-off between planar grinding time (abrasive size) and induced damage. In some cases for ceramics, it is better to take more time and minimize damage at planar grinding in order to reduce overall polishing times. The use of SIAMAT colloidal silica also provides a chemical mechanical polishing (CMP) action which is the most effective means for eliminating both surface and subsurface damage. The combination of SIAMAT colloidal silica with DIAMAT polycrystalline diamond also produces the required surfaces finishes.

SECTIONING

Diamond Wafering blade - medium grit / low concentration

MOUNTING

Castable Mounting with Epoxy or Acrylic resins.

POLISHING

*Required for central polishing force. Click here for more information on central vs. individual polishing force polishing.

|

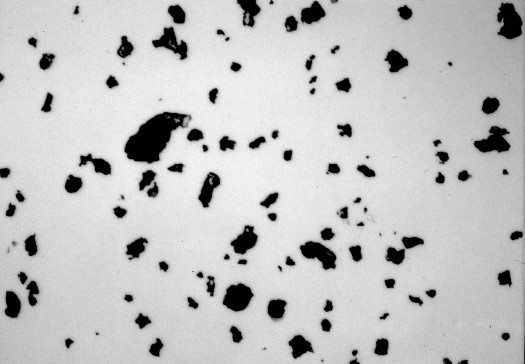

| Mullite, 400X (B.F.) as polished condition |

Common Etchants

CAUTION:Safety is very important when etching. Be sure to wear the appropriate protective clothing and observe all WARNINGS on chemical manufacuters SDS (Safety Data Sheets). Also review the COMMENTS and CONDITIONS Section for each etchant.