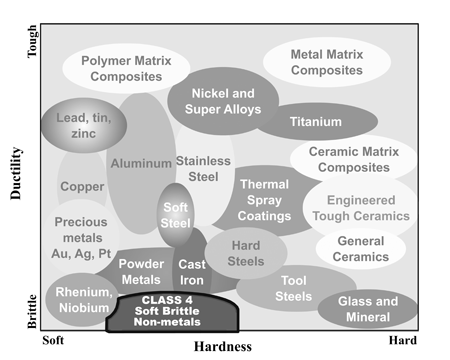

Nickel-Zinc Ferrite

Specimen Preparation (Class 4 Procedures)

|

Ferrite ceramics produce one of the strongest types of magnetics, and consist of iron, boron and barium, or strontium and molybdenum. A ferrite material is a ceramic magnet which has high magnetic permeability, which allows it to store stronger magnetic fields than iron.

Specimen preparation of friable or brittle materials such as ferrites can be difficult. Proper microstructural preparation of these materials must maintain the structure of the Ni-Fe ferrite structure. This is accomplished by mounting the ferrite in a castable mounting compound such as epoxy. Initial grinding with a 320 grit or finer SiC paper is required to prevent pulling out the ferrite particles, especially the smaller particles. Rough polishing is accomplished on woven polishing cloths using diamond, with final polishing on high napped cloth using a polycrystalline alumina abrasive.

SECTIONING

Diamond wafer cutting with medium grit / low concentration diamond blades

MOUNTING

Castable mounting acrylics or epoxies

POLISHING

*Required for central polishing force. Click here for more information on central vs. individual polishing force polishing.

|

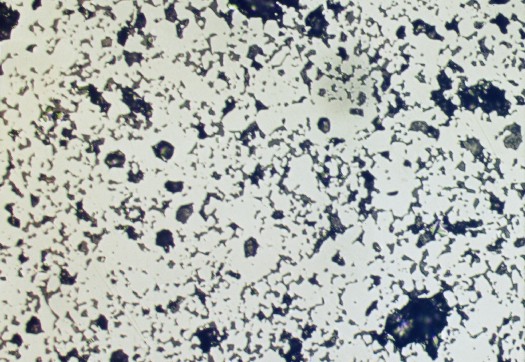

| Ni-Zn ferrite, 400X (B.F.), as polished condition |

ETCHING

Common Etchants

CAUTION:Safety is very important when etching. Be sure to wear the appropriate protective clothing and observe all WARNINGS on chemical manufacuters SDS (Safety Data Sheets). Also review the COMMENTS and CONDITIONS Section for each etchant.