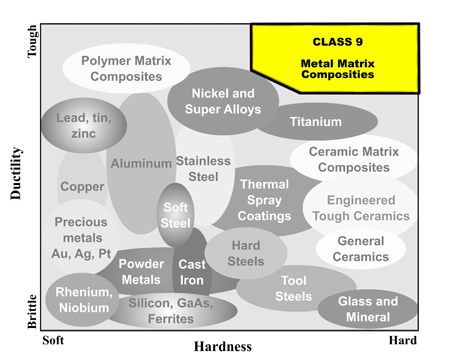

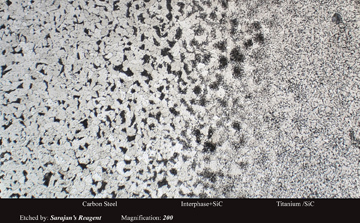

SiC particles in Titanium Matrix Welded to Carbon Steel (MMC)

Specimen Preparation (Class 9 Procedures)

|

Welding of disimilar metals can be challenging due to the individual properties, including melting temperatures and chemical compositions of the various metals. This is complicated more if one or more of the disimilar metals is a composite material. By analyzing the microstructure and the heat affected zone (HAZ), the quality, strength and properties of the metal interface can be examined.

SECTIONING

Diamond Wafering blade - medium grit / low concentration)

MOUNTING

Castable Mounting with Epoxy or Acrylic resins

POLISHING

*Required for central polishing force. Click here for more information on central vs. individual polishing force polishing.

|

| SiC-Titanium / Carbon-steel Weld, 200X, Etched Sarajan's Reagent (73% DI water, 16% HF, 6% HNO3, 5% HCl) |

Common Etchants

CAUTION:Safety is very important when etching. Be sure to wear the appropriate protective clothing and observe all WARNINGS on chemical manufacuters SDS (Safety Data Sheets). Also review the COMMENTS and CONDITIONS Section for each etchant.