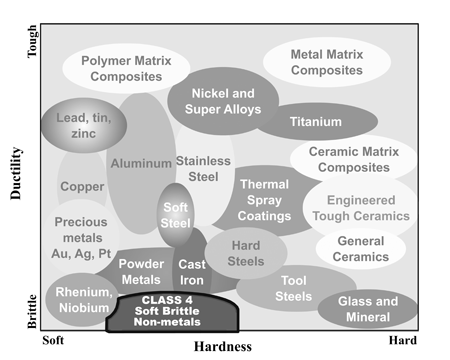

Silicon Substrate

Specimen Preparation (Class 4 Procedures)

|

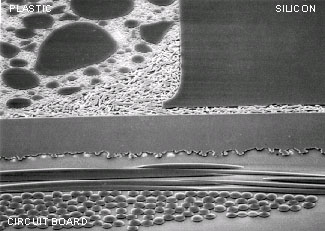

Specimen preparation of friable or brittle materials such as silicon offer a microstructural preparation challenge. Proper microstructural preparation of these materials must minimize fracturing the silicon structure. This is accomplished by first by cutting or sectioning with fine grit / low concentration diamond blades. Oftentimes microelectronic cross sections are not encapsulated and just mounted using a hot melt tape. If the specimens are encapsulated, a castable mounting compound such as an acrylic or an epoxy is recommended. Initial grinding and polishing with diamond lapping films is required to prevent undue damage to the silicon during grinding. Rough polishing is accomplished on low napped polishing cloths using diamond, with final polishing for a very short time on a high napped cloth using collodial silica.

SECTIONING

Diamond Wafering blade - fine grit / low concentration

MOUNTING

Hot melt tape or castable mounting with Epoxy or Acrylic resins

POLISHING

*Required for central polishing force. Click here for more information on central vs. individual polishing force polishing.

|

|

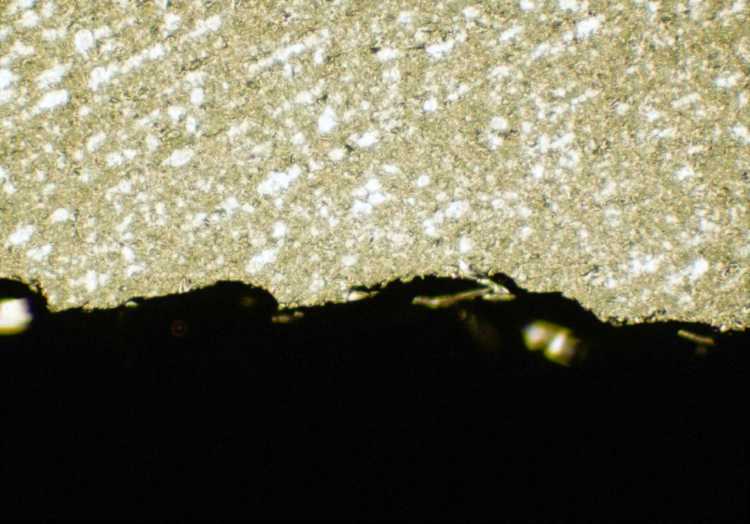

| Fine grit diamond wafering blade | Medium grit diamond wafering blade |

|

|

| Electronic package | Electronic package |

ETCHING

Common Etchants

CAUTION:Safety is very important when etching. Be sure to wear the appropriate protective clothing and observe all WARNINGS on chemical manufacuters SDS (Safety Data Sheets). Also review the COMMENTS and CONDITIONS Section for each etchant.