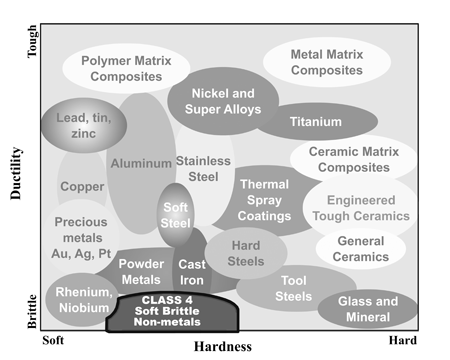

Solder Joints on Ceramic Substrates

Specimen Preparation (Class 4 Procedures)

|

The microstructural preparation of electronic packages presents some very difficult challenges, such as abrasives embedding in very soft solder joints, edge rounding, polishing relief between very hard (ceramic) or brittle (silicon) materials and the very soft plastic and metal solders. The use of alumina lapping films are very useful for maintaining flatness and for minimizing fractured abrasive embedding for non-ceramic substrates. For specimens with ceramic substrates, diamond lapping films are recommended.

SECTIONING

Diamond Wafering blade - medium grit / low concentration)

MOUNTING

Castable Mounting with Epoxy or Acrylic resins

POLISHING

*Required for central polishing force. Click here for more information on central vs. individual polishing force polishing.

|

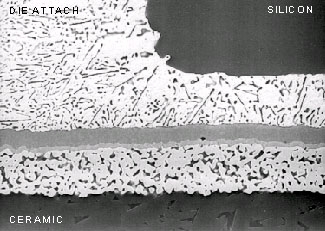

| Electronic die cross section. |

|

| Electronic die cross section |

ETCHING

Common Etchants

CAUTION:Safety is very important when etching. Be sure to wear the appropriate protective clothing and observe all WARNINGS on chemical manufacuters SDS (Safety Data Sheets). Also review the COMMENTS and CONDITIONS Section for each etchant.