Zinc and Zinc Alloy

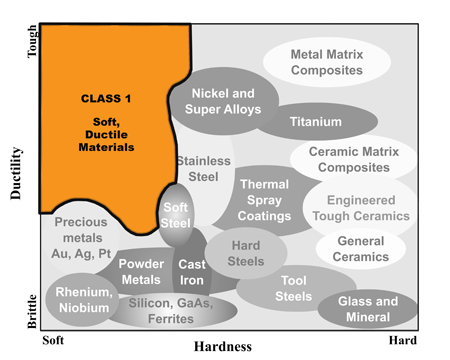

Specimen Preparation (Class 1 Procedures)

|

Pure zinc can be difficult to prepare because it forms abrasion artifacts in the form of small recrystallized grains which often produce twinning. Proper preparation requires minimizing damage. For pure zinc alternating between polishing and etching and repolishing is often required in order to remove the damaged microstructure. The recommended etchant is 10 grams of sodium hydroxide in 100 ml D.I. water; etch for only a few seconds before repolishing.

SECTIONING

MAXCUT Abrasive blade (Cat. No. MAX-C or MAX-I series)

MOUNTING

Compression Mounting with Phenolic, Epoxy or Diallyl Phthalate compression mounting resins

POLISHING

*Required for central polishing force. Click here for more information on central vs. individual polishing force polishing.

|

| Pure zinc, 100X (DIC), etchant 10 grams NaOH in 100 ml D.I.water for 5 seconds |

|

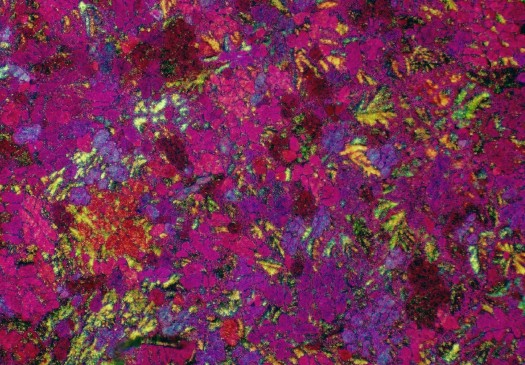

| Zinc-Aluminum alloy, 100 X Polarized Light, Etchant 40 gms CrO3, 3 gms Na2SO4, 200 ml DI water. |

ETCHING

Common Etchants

CAUTION:Safety is very important when etching. Be sure to wear the appropriate protective clothing and observe all WARNINGS on chemical manufacuters SDS (Safety Data Sheets). Also review the COMMENTS and CONDITIONS Section for each etchant.