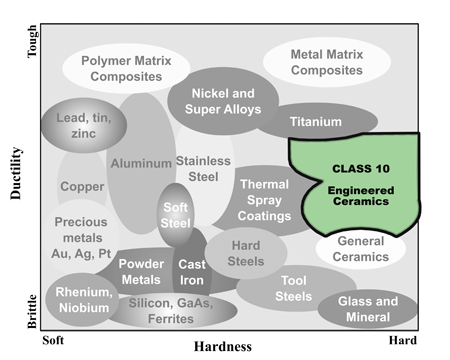

Zirconia Engineering Ceramic

Specimen Preparation (Class 10 Procedures)

|

Partially stabilized zirconia is actually a fairly easy material to prepare. Care must be taken not to produce excessive damage during cutting and initial grinding which may cause the stress induced crystal structure from the tetragonal phase to the monoclinic phase. To minimize sectioning damage it has been found that cutting zirconia at high loads (feed rates) and high speeds provides the best combination. Rough grinding is then accomplished with a metal mesh cloth and 30-micron polycrystalline diamond. Rough polishing with a POLYPAD pad or TEXPAN pad using a combination of 6-micron polycrystalline diamond and SIAMAT colloidal silica provide a chemical-mechanical-polishing (CMP) action. Final polishing on a DACRON cloth with 1-micron diamond and colloidal silica produces a surface ready for microstructural etching and examination.

SECTIONING

Diamond Wafering blade - medium grit / low concentration

MOUNTING

Castable Mounting with Epoxy or Acrylic resins.

POLISHING

*Required for central polishing force. Click here for more information on central vs. individual polishing force polishing.

|

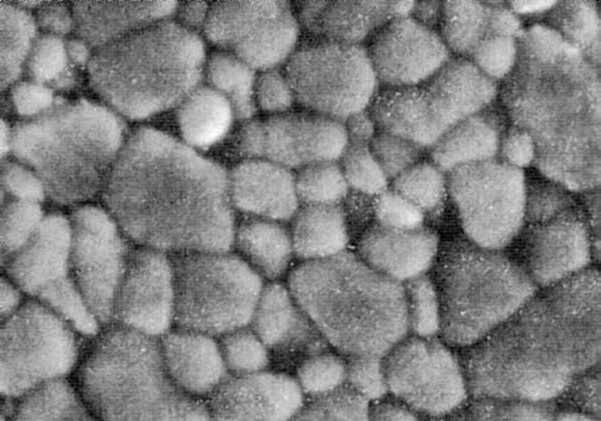

| Yittria stabilized Zirconia, 15,000X, thermally etched |

Common Etchants

CAUTION:Safety is very important when etching. Be sure to wear the appropriate protective clothing and observe all WARNINGS on chemical manufacuters SDS (Safety Data Sheets). Also review the COMMENTS and CONDITIONS Section for each etchant.