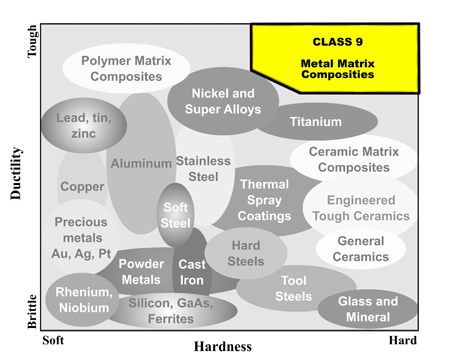

ZrB2 particles in Titanium Matrix (MMC)

Specimen Preparation (Class 9 Procedures)

|

Hard particles in a metal matrix can be difficult to microstructurally prepare because of particle pull-out as well as excessive relief between the particles and the matrix. The key to preparation of metal matrix composites is to minimize damage at each preparation stage. This includes sectioning with the appropriate diamond wafering blade and using the finest practical abrasive for initial grinding. Polishing with SIAMAT colloidal silica provides a chemical mechanical polishing (CMP) action which is the most effective means for eliminating both surface and subsurface damage. The combination of SIAMAT colloidal silica with DIAMAT polycrystalline diamond also produces the required surfaces finishes in a minimal amount of time.

SECTIONING

Diamond Wafering blade - medium grit / low concentration

MOUNTING

Castable Mounting with Epoxy or Acrylic resins.

POLISHING

*Required for central polishing force. Click here for more information on central vs. individual polishing force polishing.

|

| Zirconium Diboride particles in a Titanium Matrix.

As polished, 400X (DIC) |

|

| Zirconium Diboride particles in a Titanium Matrix Etched, 1000X (DIC) |

Common Etchants

CAUTION:Safety is very important when etching. Be sure to wear the appropriate protective clothing and observe all WARNINGS on chemical manufacuters SDS (Safety Data Sheets). Also review the COMMENTS and CONDITIONS Section for each etchant.