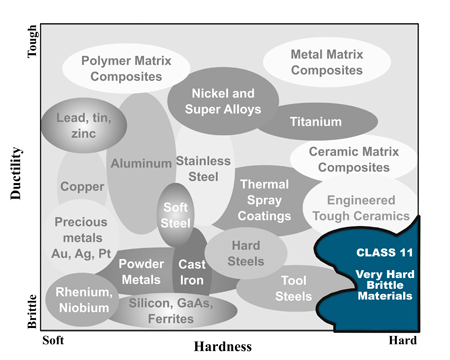

CuFeS2 / MoS2 Mineral Concentrate

Specimen Preparation (Class 11 Procedures)

|

The microstructural analysis of mining concentrates or tailings is useful in determining if the important minerals have been liberated from the gang material through grinding. In this example, a concentrate of chalcopyrite and molybdenite are to be separated by a secondary floatation process. For this to be effective the chalcopyrite and the molybdenite minerals need to be separated. If they are not, an additional or an extended grinding operation may be required. Proper microstructural preparation of these materials must maintain the structure of the ore concentrate. In other words, microstructural grinding and polishing must not liberate any minerals that are locked together. This is accomplished by first mounting the mineral in a castable mounting compound such as epoxy. Initial grinding with a 320 grit or finer SiC paper is required to prevent pulling out the mineral particles, especially the smaller particles. Rough polishing is accomplished on low napped polishing cloths using diamond, with final polishing for a very short time on a high napped cloth using an alumina suspension.

SECTIONING

Not required

MOUNTING

Castable Mounting with Epoxy or Acrylic resins

POLISHING

*Required for central polishing force. Click here for more information on central vs. individual polishing force polishing.

|

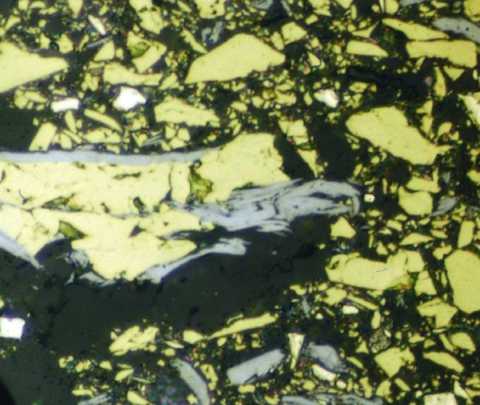

| CuFeS2/MoS2 Mineral.

Note that the two minerals have not been completely liberated from each other. |

|

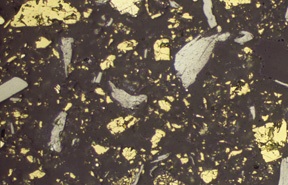

| CuFeS2/MoS2 Mineral.

Note the separation of the two minerals. |

ETCHING

Common Etchants

CAUTION:Safety is very important when etching. Be sure to wear the appropriate protective clothing and observe all WARNINGS on chemical manufacuters SDS (Safety Data Sheets). Also review the COMMENTS and CONDITIONS Section for each etchant.